Remanufacturing the

Minolta Color Pageworks Toner Cartridges. (Lexmark SC-1275)

0251

The Minolta Color Pageworks engine was first

released in June 1997. It has been surprising in its staying power

as it is still very popular. The engine itself is a 12ppm Black,

3ppm color 600 Dpi engine. The toner cartridges are very simple to

do. They basically consist of a toner hopper and the developer

roller. The developer roller has a sleeve similar to the Minolta

SP-6 (Epson Action Laser 1500). The same care must be taken not to

damage the sleeve, but other than that, they are very simple to do.

As with most other color lasers, this machine uses a transfer belt

unit. This belt takes the color/black images off the drum and

transfers the finished image on to the paper. The transfer belt unit

is rated for 100,000 pages.

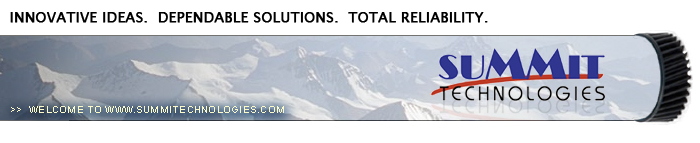

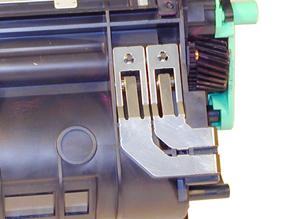

Each color cartridge has a different fin

location that only allows that color cartridge to go into the proper

slot (See Figure 1). Because of this, as well as the fact that it is

virtually impossible to get all the old toner out, we do not

recommend that any cartridges be converted into another color.

Minolta and Lexmark cartridges are not interchangeable. We have

colorized the tabs so you can see the difference better

Each toner cartridge uses a fuse to tell the

printer that a new cartridge has been installed. The fuse is a 5 x

20mm, 80mA 250V Fast acting glass type fuse. This fuse must be

replaced each cycle. The two windows located on each cartridge are

used to determine the toner level. The sensor is in the printer. It

fires a light into the toner cartridge that is reflected back by a

mirror inside the toner cartridge. The amount of light reflected

back determines the amount of toner left. A small LED also lights

up which is reflected back by the cartridge shell. This determines

if a cartridge is present.

The Lexmark cartridges are the:

1361751 Black 4,500 pages @5%

1361752 Cyan 3,500 pages @5%

1361753 Magenta 3,500 pages @5%

1361754 Yellow 3,500 pages @5%

1361750 OPC Drum 20,000 Mono, 5,000 Color pages @5%

The current Minolta cartridges are the:

1710437-001 Black 4,500 pages 5%

1710437-004 Cyan 3,500 pages 5%

1710437-003 Magenta 3,500 pages 5%

1710437-002 Yellow 3,500 pages 5%

1710438-001 OPC Drum 20,000 Mono, 5,000 Color pages @5%

The old Minolta part numbers are the:

1940-501, 0940-701, 0940-401, 0940-601

Machines based on the Minolta Color

Pageworks engine are:

Lexmark Optra SC 1275

Lexmark Optra SC 1275n

Lexmark Optra SC 1275n Solaris

Lexmark Optra SC 5040

Minolta Color PagePro

Minolta Color Pageworks EX

Minolta Color Pageworks EX Plus

Minolta Color Pageworks L

Minolta Color Pageworks LN

Minolta Color Pageworks N

Minolta Color Pageworks Plus

Minolta Color Pageworks PS

Minolta Color Pageworks PS Plus

Machine and cartridge troubleshooting as

well as running test prints are covered at the end of this article.

-

160g Black toner

-

140g Cyan, Magenta, Yellow toner

-

Replacement 5 x 20mm, 80mA, 250V fast

acting glass type fuse

-

Phillips head screwdriver

-

Small common screw driver

-

Phillips head jewelers screwdriver

-

Spring Hook

-

Vacuum approved for toner

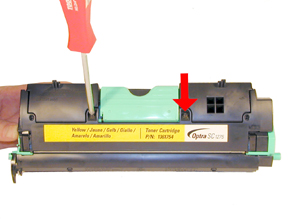

1) Remove the fill plug. Dump out any

remaining toner, and vacuum the chamber as clean as possible. See

Figure 2

2) Remove the two very small screws on

either side of the top with a Phillips head jewelers screwdriver

See Figure 3

3) Remove the two larger screws from the

top handle area. The top cover will come loose at this point. The

spring loaded handle will also come loose. Be careful not to lose

the spring. Remove the top cover and handle. See Figure’s 4 & 5

|

|

Figure 1 |

Figure 2 |

|

|

Figure 3 |

Figure 4 |

4) Lift up on the left side (non-gear

side) of the developer roller cover and remove. See Figure 6

5) On the opposite side, release the

spring from the cover. Remove the cover and spring. See Figure’s 7

& 8

|

|

Figure 5 |

Figure 6 |

|

|

Figure 7 |

Figure 8 |

6) Remove the two tension springs on

either side of the developer roller. See Figure 9

7) Remove the three very small screws from

the smaller green end cap with the Phillips head jewelers

screwdriver. Remove the end cap. See Figure 10

8) On the opposite side, two very small

and one large screw from the large green end cap. Remove the end

cap. See Figure 11

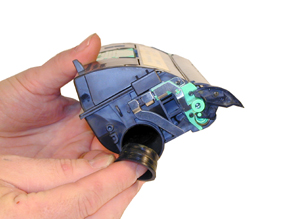

9) Remove the developer roller assembly.

Be very careful not to damage the sleeve, it is very fragile. Do

not clean the sleeve with any chemicals; carefully wipe it off

with a clean lint free cloth only. Be careful not to lose the

drive gear or spacers. See Figure 12.

|

|

Figure 9 |

Figure 10 |

|

|

Figure 11 |

Figure 12 |

10) Remove the large double drive gear.

This gear is easily lost. See Figure 13

11) Remove the two screws from the doctor

blade. Carefully lift the blade up,(but do not remove) so that any

remaining toner can be removed. Be very careful not to tear the

foam seals attached to the blade. Clean any toner buildup on the

edge of the doctor blade with a foam swab. It can be cleaned with

alcohol, but make sure it is dry before re-installing. Also make

sure not to drip any alcohol into the cartridge. See Figure’s 14 &

15

12) Re-install the doctor blade and two

screws. Be careful not to damage the seals, and make sure the

metal blade on the right side is making contact with the blade.

See Figure 16

|

|

Figure 13 |

Figure 14 |

|

|

Figure 15 |

Figure 16 |

13) Install the cleaned developer roller

assembly into the chamber. Be careful not to damage the thin

plastic shims on either side of the roller. See Figure’s 17 & 18

NOTE: It is very easy to get grease

from the gears on your fingers, and accidentally transfer it to

the developer roller. Be very careful not to do this. If it does

happen, the roller should be replaced. Cleaning it with any type

of solvent, will most likely strip part of the coating off the

sleeve, and cause print defects.

14) Install the large double drive gear.

See Figure 19

15) Install the large end cap on the gear

side of the cartridge and three screws. Make sure that the long

plastic finger is over the developer roller tape tensioner. See

Figure’s 20 & 21

|

|

Figure 17 |

Figure 18 |

|

|

Figure 19 |

Figure 20 |

16) Install the small end cap and three

screws. Also make sure the long finger is over the developer

roller tape tensioner. See Figure 22

17) Install the two large springs on the

tape tensioners. See Figure 23

18) Install the coil spring on the end

cap. See Figure 24

|

|

Figure 21 |

Figure 22 |

|

|

|

Figure 23 |

Figure 24 |

19) Install the developer roller cover

onto both posts. Make sure the spring is engaged properly. See

Figure’s 25 & 26

20) Set the spring on the top cover

handle. Install the top cover so that the handle spring is loaded

properly. See Figure’s 27 & 28

|

|

Figure 25 |

Figure 26 |

|

|

|

Figure 27 |

Figure 28 |

21) Install the two large screws on the

top cover first and then the two small screws. See Figure’s 29 &

30

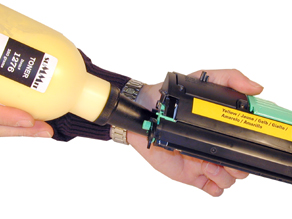

22) Fill with 160g black or 140g color

toner. See Figure 31

23) Install the fill plug, check for

leaks. See Figure 32

24) Install the replacement fuse by gently

prying the two contacts up from the cartridge. Pry them up from

the flat contact side, and lift up. If you pry them up from the

post side, the post may break, making the cartridge almost

useless. See Figure’s 33 & 34

|

|

|

Figure 29 |

Figure 30 |

|

|

|

Figure 31 |

Figure 32 |

|

|

|

Figure 33 |

Figure 34 |

Make sure the READY light is on.

Press the “MENU” button until Utilities

MENU appears on the display.

Press “SELECT”

Press the “MENU” button until either PRINT

FONTS or PRINT MENUS appears on the display. Choose the page you

want to print, and Press “SELECT”.

The chosen page will print out.

There is really not much that can go wrong

with these cartridges. Most of the problems come from either the

developer roller or the DR. blade. Streaking, shading,

back-grounding...all can come from these two parts. Make sure they

are clean, and not damaged.

Machine Troubleshooting

As with most machines these days, most of the error codes

are in plain English. There are however, a few messages that are

numeric. They are as follows:

920: Fuser error

930: Print head (laser) error

944-954: Controller card error

960-965: Emulation error

977: Network card error

© 2003-2004 Summit Laser Products, Inc.

Any attempt to reproduce any part of these instructions without the written

consent of Summit Laser Products, Inc is prohibited. All registered trademarks

are the property of their respective owners.

|