Remanufacturing

the Xerox 4525 Toner Cartridge

0317

First released in April 2001, the Xerox 4525

is based on a 45 ppm 1200 Dpi engine. While it looks like an N24

cartridge there are differences, but most importantly the toner is

different. The higher speed of these machines calls for a toner that

melts at a different temperature than the N24. Most of the other

parts used in the cartridge are standard N24, but the toner is not.

Machines based on the Xerox 4525 engine are

as follows:

Lexmark W820, 820DN, 820E, 820N Cartridge # 12B0090

IBM InfoPrint 1145, 1145DN, 1145N Cartridge # 28P1882

Xerox DocuPrint N4525, 4525BX, 4525CN, 4525FM Cartridge # 113R00195

All three cartridges are rated for 30,000

pages at 5% coverage.

Acom also makes a MICR Enhanced version of the Xerox 4525, but as of

now, no toner or chips are available for it.

These cartridges all use N24 type chips that

must be replaced each cycle. Each cartridge has its own chip. Make

sure you know which machine your customer has before installing the

chip. The cartridge will not print if the wrong chip is installed.

Unlike the N24 cartridges, these do not have

all the variations to worry about. They are very simple to do, work

great and with a list price of $372.00, very profitable!

Running test prints as well as cartridge

troubleshooting will be covered at the end of this article.

1) Vacuum the exterior of the cartridge.

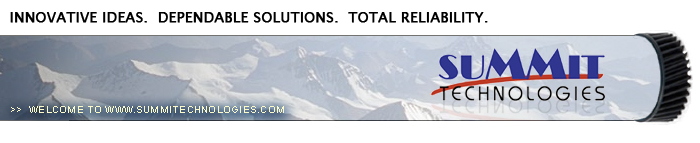

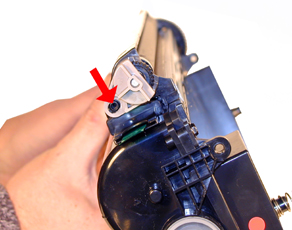

2) On each side of the cartridge there is

a large metal pin.

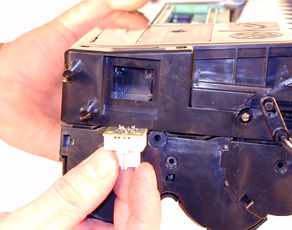

3) Carefully pull these pins out using

either a pair of needle nose pliers or wire cutters. See Figure’s

1 & 2

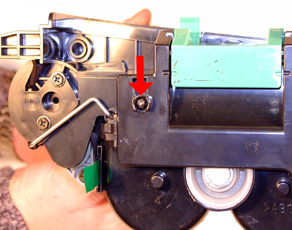

4) Remove the Waste Chamber and put the

toner hopper aside. See Figure 3

5) Remove the two screws on each side of

the drum axle plates, remove the Plates. See Figure’s 4 & 5

|

|

Figure 1 |

Figure 2 |

|

|

Figure 3 |

Figure 4 |

6) Remove the Drum from the cartridge. See

Figure 6

7) Remove the Primary Charge Roller (PCR).

Clean with your preferred PCR cleaner. See Figure 7

8) Remove the top cover of the Waste

Chamber by removing the 4 screws. One is hidden under the label,

and one is under the handle. See Figure 8

|

|

Figure 5 |

Figure 6 |

|

|

Figure 7 |

Figure 8 |

9) Remove the tape seal from the right

side. Pry the cover up from the bottom edge. See Figure’s 9 & 10

10) Clean all the toner out of the waste

chamber.

NOTE: Be very careful not to bend

or otherwise damage the small thin recovery blade located next to

the Wiper Blade when vacuuming. If this blade is bent down lower

than the height of the wiper blade, toner will accumulate on top

of the blade and spill into the printer. If the blade does get

bent, it should be replaced.

11) Remove the Wiper Blade (2 screws and

spacers, lift up and out). DO NOT lose the spacers! This blade has

a tight fit, work it loose form both edges and lift out. See

Figure’s 11 & 12

|

|

Figure 9 |

Figure 10 |

|

|

Figure 11 |

Figure 12 |

12) Coat the NEW wiper blade with your

preferred lubricant and install. See Figure 13

13) Replace the two screws and spacers.

Make sure the flat side of the spacers is facing the foam. That

way the foam will not be pinched by the spacer possibly causing a

leak. See Figure’s 14 & 15

14) Install the top cover front edge

first. Press down so the back tabs lock in place, install the four

screws, and the tape seal on the right side. See Figure’s 16, 17 &

18

|

|

Figure 13 |

Figure 14 |

|

|

Figure 15 |

Figure 16 |

|

|

Figure 17 |

15) Install the cleaned PCR. See Figure 19

16) Install the white gear side of the

drum to the white PCR holder side of the cartridge. See Figure 20

17) Install the two drum end caps, and

screws. See Figure’s 21 & 22

|

|

Figure 18 |

Figure 19 |

|

|

Figure 20 |

Figure 21 |

18) Remove the fill plug, and dump any

remaining toner out.

19) On the small drive gear side of the

supply chamber, remove the screw, and Magnetic roller end cap. See

Figure 23

20) Carefully remove the magnetic roller,

vacuum clean and place aside. See Figure 24

21) Remove the two screws and DR blade.

See Figure 25

|

|

Figure 22 |

Figure 23 |

|

|

|

Figure 24 |

Figure 25 |

22) Vacuum the Toner hopper thoroughly.

23) Install the seal so that the tail is

on the small drive gear side. Make sure the tail fits into its

slot, and comes out through the seal channel. See Figure’s 26 & 27

24) Fill the hopper with 1350g of

dedicated W820 toner. As explained in the beginning of this

article, normal N24 toner will not work in these cartridges due to

the higher printing speed of the machines. Check for leaks. See

Figure 28

25) Replace the DR blade and two screws.

See Figure 29

|

|

Figure 26 |

Figure 27 |

|

|

|

Figure 28 |

Figure 29 |

26) Turn the bushing on the magnetic

roller assembly so that the curved side is facing up. Pull it away

from the roller slightly, and install the entire assembly into the

hopper. Press the bushing in so that it is seated properly, and

press the drive gear back on the keyed shaft. See Figure’s 30, 31

& 32

27) Install the end cap and screw. Note

that both the end cap and Magnet shaft are keyed. Make sure that

the roller turns freely. See Figure 33

28) Re-assemble the cartridge by placing

the two halves together. Make sure that the springs fit into their

respective holes. See Figure 34

29) Install the two large hinge pins into

each side. See Figure’s 35 & 36

30) Replace the chip with the correct chip

for your cartridge. The IBM 1145, Lexmark W820, and Xerox 4525 all

use different chips. See Figure 37

|

|

|

Figure 30 |

Figure 31 |

|

|

|

Figure 32 |

Figure 33 |

|

|

|

Figure 34 |

Figure 35 |

|

|

|

Figure 36 |

Figure 37 |

Make sure the READY light is on.

Press the “MENU” button until Utilities

MENU appears on the display.

Press “SELECT”

Press the “MENU” button until either PRINT

FONTS or PRINT MENUS appears on the display. Choose the page you

want to print, and Press “SELECT”.

The chosen page will print out.

There are no strange or unique issues that

we have seen with these cartridges. Normal cartridge problems along

with the repetitive defect rate are listed below

Primary Charge Roller (PCR); The

primary charge roller if dirty will show on the test print as

vertical gray streaks down the page, or as a gray background

throughout the page. If there is any physical damage, it will repeat

at intervals of 44mm.

A Dirty PCR Connection will result in

dark black horizontal bars across the page, or as shading throughout

the page.

A Scratched Drum will show up as a

very thin, perfectly straight line that runs from the top to the

bottom of the test page.

A Chipped Drum will result in a dot

or series of dots that repeat at 95mm intervals

A Damaged Magnet Roller Sleeve will

either leave a mark or a blank spot (depending on the type of

damage) at intervals of 56mm.

A Worn Magnetic Roller Sleeve will

cause light prints. (You can normally see the silver through the

black coating on a worn mag.)

A Light Damaged Drum will show up as

a shaded area on the test print that should be white. Again

this will repeat at intervals of 95mm.

A Bad Wiper Blade will result in

vertical gray lines down the page, or as shading across the entire

page. In either case there will be a film of toner on the drum

surface.

© 2003-2004 Summit Laser Products, Inc.

Any attempt to reproduce any part of these instructions without the written

consent of Summit Laser Products, Inc is prohibited. All registered trademarks

are the property of their respective owners.

|