*Lexmark T-630 Toner Cartridges

DOC-0324

First introduced in June 2001, the Lexmark T630 series

is based on the Lexmark T630 1200 dpi engine. Depending on the model, the

print speed is from 30-45 pages per minute. As with all of Lexmark’s new heavy

duty machines these machines are loosely based on the older Optra S machines

but these are much faster. Due to the speed and fuser characteristics, the

toner is completely different. This toner is also different from the T620

series.

The machines currently available based on the T630

engine are:

| T630 |

T630dn |

T630n |

| T630 |

T632dtn |

T632dtnf |

| T632n |

T634 |

T634dtn |

| T634dtnf |

T634n |

T634tn |

As with the T520/T620 machines, these cartridges have ARD (Anti-Recycling

devices) installed in the Prebate or “Return Program” cartridges that will not

allow the cartridge to be used again until the chip board is replaced. As with

other Lexmark cartridges, the Non-prebate or standard cartridges will work

with out replacing the chips. Lexmark seems to have abandoned the Prebate name

and gone with “Return Program” instead. Same mess, different name! The

programming used in these chips is similar to the code used in the new T420

series. Lexmark has added a few new wrinkles to the code that is making it a

little harder to develop a repair chip. It is currently being worked on and at

the time of this writing (May,2003), chips are not available. They should be

available as you read this. Check with your chip vendor to see if they are

available.

The Encoder wheel in these cartridges does not

indicate the toner yield as in the Optra S cartridges, that is now done by the

chip. The encoder wheel only indicates if the cartridge is a Prebate or not.

For cartridges used in MICR only machines, make sure

that the chip you are using is a dedicated MICR chip. This is also strictly a

chip function. If the cartridge is to be used in other than a Lexmark machine

the chip is different again. So far IBM, Dell, and Toshiba have not released

any machines using this engine, but they probably will. As the chip will again

be different, check with your chip supplier to make sure that their chip will

work with your machine.

All that being said, these cartridges have a huge

profit potential (See below). Even with the extra cost of the chip, and having

to be careful what machine it goes into, they are more than worthwhile to do.

The Lexmark Part #'s for these cartridges are as

follows:

|

“Return Program” 5K* cartridge: 12A7460 list $99.00** |

|

“Return Program” 21K* cartridge: 12A7462, List

$330.00** |

|

“Return Program” 32K* cartridge:

12A7465, List $355.00** |

|

Standard 5K* cartridge: 12A7360

list $149.00** |

|

Standard 21K* cartridge: 12A7362, List $380.00**

|

|

Standard 32K* cartridge: 12A7365, List $405.00** |

* Yield based on 5% coverage

** List prices current as of May 27th 2003

There are also two label cartridges, the 12A7468, and

the 12A7469.

Lexmark only lists the extra high yield cartridges

(32K) for the T632 and the T634 series. The lower yield cartridges will give

an unsupported cartridge error. The same will happen if the extra high yield

cartridge is installed in the T630 machines.

The T63x series of cartridges are different physically

from the T620 in that they have two large notches in the front edge of the

waste chamber. Since all of the cartridges from the Optra S on are somewhat

similar, we are showing all the different cartridge versions here. See

Figure’s 1-6

|

FIGURE 1

|

FIGURE 2

|

|

|

|

FIGURE 3 |

FIGURE 4

|

FIGURE 5 |

FIGURE 6 |

As with the Optra S machines, the Primary Charge Roller (PCR) is not in the

cartridge, it's in the printer, and is rated for 300,000 pages. The Wiper

Blade inside the cartridge has an external felt brush that keeps the PCR

clean. Some of the starter cartridges have wiper blades without this felt. It

is very important that the blade be replaced with a new one that has the felt.

Otherwise a buildup on the PCR may occur.

It should also be noted that because of the play

between the toner hopper and the OPC drum, a shipping lock should be installed

in every cartridge. This holds true even if you are going to hand deliver the

cartridge. This holds true for all the cartridges based on the Optra S design.

Machine Cartridge/troubleshooting as well as how to

run test prints will be covered at the end of this article.

-

T-630 Toner: Use 188g for the 5K cartridge, 780g for

the 21K cartridge, and 1200g for the 32K cartridge

-

Drum padding powder (Kynar) Do NOT use Zinc Sterate

on these cartridges!

-

Cotton Swabs

-

Isopropyl Alcohol

-

Cotton Pads

-

Long life OPC Drum (Optional)(4059 Style)

-

Wiper Blade (4059 Style with PCR cleaner!)

-

Shipping Lock

-

Felt Wand (4059 Style)

-

Recovery Blade (4059 Style)

-

Retaining Blades

-

Vacuum the exterior of the toner cartridge. Be

careful of the drum!

-

Place the cartridge on the bench drum side up (Label

face down), with the toner supply towards you.

-

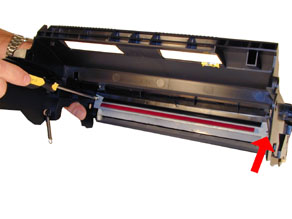

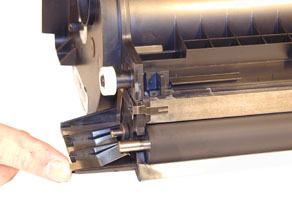

With a spring hook, remove the two springs from each

end of the cartridge. See Figure 7

-

There are two plastic posts from the hopper that fit

into the cartridge shell. Pull the edge of the shell out to release the

posts, and lift up the hopper so that the posts are free. See Figure 8

-

Slide the hopper to the right, and remove from the

cartridge. Pull it out so that the large white bearing comes free. Place the

hopper aside. See Figure 9

-

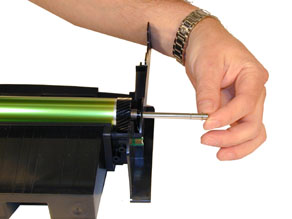

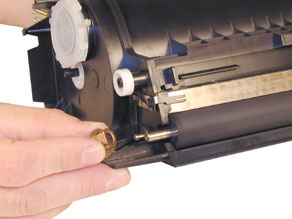

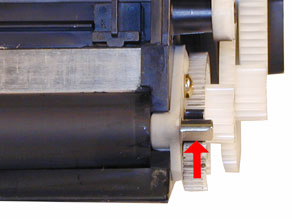

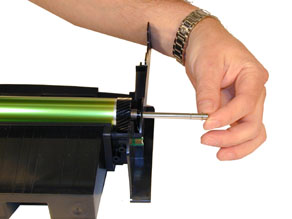

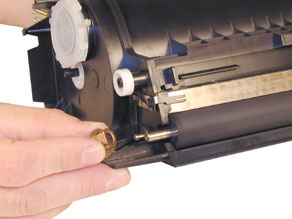

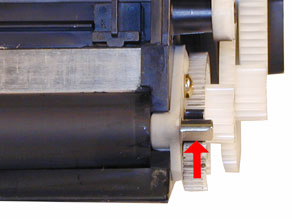

Remove E-Ring from the small white helical gear end

of the drum axle. There is no need to remove the opposite E-ring. See Figure

10

FIGURE 7 |

FIGURE 8 |

| |

|

FIGURE 9 |

FIGURE 10 |

-

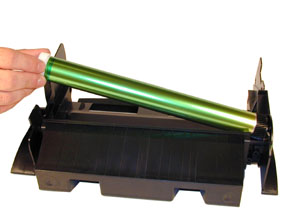

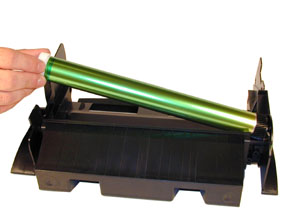

Slide the Drum Axle out of the cartridge. Hold the

small helical gear while pulling it out so that the drum is not damaged in

the process. Note the location of the small spring. See Figure’s 11 & 12

-

Gently lift the Drum up and out of the cartridge,

if you are going to reuse the drum, place it in a light protected area. Be

careful not to lose the spring, its’ purpose is to keep the drum from

rotating backwards. See Figure 13

-

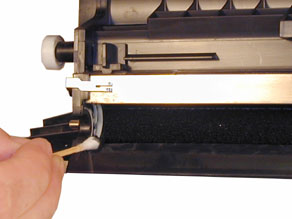

Remove the Wiper Blade by removing the two screws

on either end of the Wiper Blade. See Figure 14

FIGURE 11 |

FIGURE 12 |

| |

|

FIGURE 13 |

FIGURE 14 |

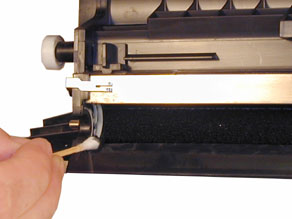

-

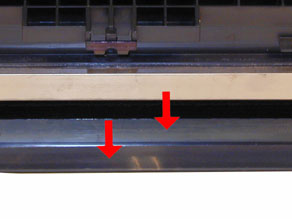

Place the cartridge so that the waste bin is

face-up. Take a razor blade and cut the foam seal that runs along the back

edge of the wiper blade to separate it from the cartridge. Make sure to

cut along the plastic/foam, and not the blade. See Figure 15

-

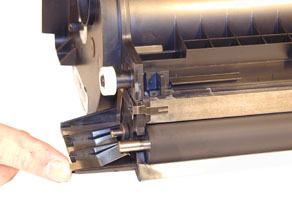

Hold the cartridge so that it is up-right

(Standing up with the waste bin on the table). With one hand, hold the

laser shutter open, and with the other hand, remove the Wiper Blade. See

Figure 16

NOTE1: The OEM Wiper Blade has the PCR

cleaning assembly attached to it. It cannot be removed from the Blade

without damaging it. Our new replacement Wiper Blades come complete with

this assembly attached. The "Starter cartridges" that came with a new

printer do not have the PCR Cleaning Assembly on the Wiper Blade. The

blades on the starter cartridges must be replaced.

-

Make sure that the two end foams are clean and in

their proper place See Figure 17

-

Pad the new Wiper Blade with Kynar padding powder,

replace the blade and two screws into the cartridge. (Don’t use Zinc

Sterate on these cartridges! See Figure 18

FIGURE 15 |

FIGURE 16 |

| |

|

FIGURE 17 |

FIGURE 18 |

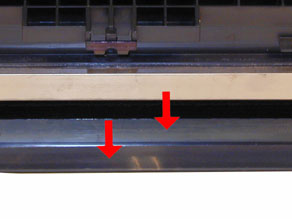

-

Place a piece of clear tape along the edge of the

Wiper Blade. If the tape does not stick well, the area should be cleaned

with alcohol. It is very important to get a good seal with the tape,

otherwise the cartridge will leak. Trim away any excess tape. See Figure

19

-

Be careful not to allow any tape into the laser

port opening!

-

With a pair of needle nose pliers, gently pry off

the Encoder Wheel. Make sure you pry it off from the center shaft so that

the wheel does not become damaged. Place the wheel in a safe place.

Remember, this wheel tells the cartridge what type of cartridge it is,

Prebate or Non-Prebate. The chip is what tells the machine what type of

yield the cartridge has. If this wheel becomes damaged, it must be

replaced. See Figure 20

-

Remove the drive gear from the developer roller

shaft. See Figure 21

-

Remove the Doctor Blade Spring by pressing down on

the center of the spring. See Figure 22

FIGURE 19 |

FIGURE 20 |

| |

|

FIGURE 21 |

FIGURE 22 |

-

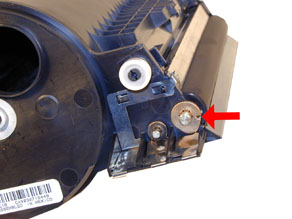

Remove the metal contact plate from under the

developer roller shaft and bushing. See Figure 23

-

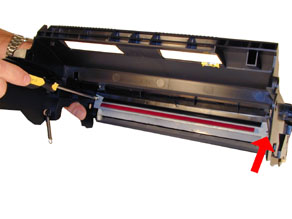

On the left (fill Plug) side of the Static Roller

there is a small metal bushing, take a small screwdriver, and pry the

bushing up so that the tab on the bushing is facing up. This will release

the bushing, and Developer Roller. See Figure 24

-

Remove the Developer Roller. Note that the spacers

are now clear instead of white. See Figures’ 25 & 26

FIGURE 23 |

FIGURE 24 |

| |

|

FIGURE 25 |

FIGURE 26 |

NOTE: Always remove the Doctor Blade Spring

before removing the Developer Roller, failure to do this will cause the

Doctor Blade to slide down from its original position and break the seal.

-

Remove the fill plug from the hopper. Pry the plug

out from the base next to the hopper. The fill plug is also a breather

cap. It is best to remove both sections at once and to clean them from the

outside. These plugs tend to leak if they have been separated. See Figure

27

-

Vacuum the Toner Hopper clean.

-

With a cotton swab dipped in alcohol, clean the

Developer Roller seals located on either end of the static roller section.

These seals are made of a white plastic. Also clean the electrical contact

that touches the Developer Roller shaft. See Figure 28

-

Carefully vacuum or blow off the Developer Roller,

Be careful not to touch the roller with your hands, or to damage this

roller in any way.

-

Inspect the inner and outer retaining blades

(Black Mylar). If they are bent in any way, they must be replaced as they

will leak. See Figure 29

-

Install the

contact plate onto the cartridge. See Figure 30

FIGURE 27 |

FIGURE 28 |

| |

|

FIGURE 29 |

FIGURE 30 |

-

Place the keyed end of the Static Roller into the

cartridge, and install the roller. See Figure 31

-

Install the bushing onto the developer roller

shaft, turning it so that the tab is facing down. This will lock the

roller in place. See Figure 32

-

Install the Doctor Blade Spring. See Figure 33

-

Fill the hopper with the appropriate amount of

toner. Remember, the amount of toner that can be placed in the cartridge

is controlled by the chip. Use 870G for the 30k cartridge, and 290g for

the 10k cartridge. Install the Fill Plug. See Figure 34

-

Install the Encoder Wheel

FIGURE 31 |

FIGURE 32 |

| |

|

FIGURE 33 |

FIGURE 34 |

-

Take the OPC drum and lightly coat with the Drum

Padding Powder,(Kynar). Do NOT use DPP (Zinc Sterate), this powder will

ruin the wiper blade.

-

Place the OPC Drum into the cartridge with the

small helical gear on the NON-Contact side of the cartridge. Make sure

that the spring is in the proper position! See Figure 35

-

Install the Drum Axle pin into the small white

gear side of the drum.

-

The Axle must be installed this way to prevent the

axle from bending and damaging the drum ground contact located inside the

drum. See Figure 36

-

Install the E-Ring on the end of the axle. See

Figure 37

-

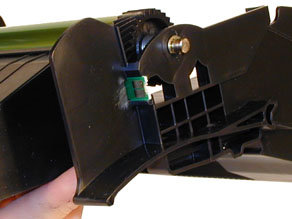

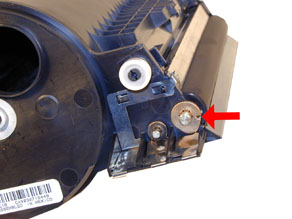

Remove the old chip with a pair of pliers, and

install the new chip. The chip will just pull out, and slide back in.

There are a few different physical versions of the aftermarket chips.

Check with your supplier for the correct instillation. See Figure 38

FIGURE 35 |

FIGURE 36 |

|

|

FIGURE 37 |

FIGURE 38 |

-

Take the Toner Hopper and install it left side

first. Make sure that the left side post, and the white bearing are in their

proper slot. See Figure 39

-

On the right side of the cartridge, pull the

cartridge shell out so that the right side post falls into its slot. See

Figure 40

-

With the spring hook, replace both springs on to the

Toner Supply Chamber. See Figure 41

-

Re-install the Developer Roller drive gear. See

Figure 42

-

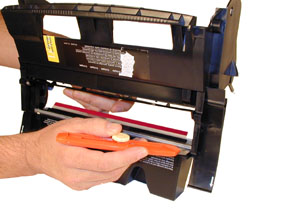

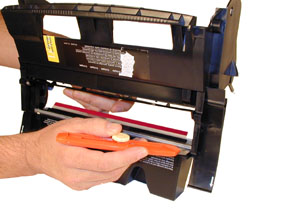

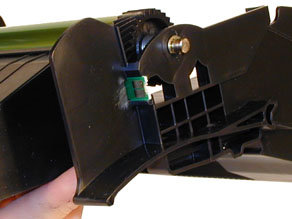

A shipping lock must now be installed. This lock

should be used even if you are going to hand deliver the cartridge. It will

prevent the toner hopper from coming in contact with the OPC Drum, and

causing damage to either the Drum or the Developer Roller. Press the two red

tabs into the sides of the cartridge as indicated in the picture supplied

with the lock. See Figure 43

-

Although the only cartridges that come with the felt

wands are the label type, we still feel that they should be included, and

changed each cartridge. After running life tests on OEM cartridges in new

machines, we have seen some dirty looking upper fuser rollers.

-

Replace the felt wand in the machine by lifting up

the external plastic cover located over the fuser assembly. This is the same

place that all the Optra S based machines use.

FIGURE 39 |

FIGURE 40 |

|

|

FIGURE 41 |

FIGURE 42 |

|

|

FIGURE 43 |

|

Dirty Primary Charge roller: Located inside

the PRINTER, this will show on the test page as vertical gray streaks down

the page, or as a gray background throughout the page.

Scratched drum: this is shown by a very thin,

perfectly straight line that runs from the top to the bottom of the test

page.

Chipped drum: This will show as a dot or

series of dots that repeat 2 times per page. Any drum defects will repeat 3

times per page based on the drum circumference of 5.2".

Light damaged drum: This will show up as a

shaded area on the test print that should be white. Again this will repeat 3

times per page.

Bad wiper blade: This will show as either a

gray line approximately 1/8" thick, or as shading across the entire page. In

either case there will be a film of toner on the drum surface.

Weak Dr. Blade Spring: This will usually show

as shaded areas on one or both sides of the page.

| Machine Error Codes: |

| 32 |

Unsupported Print cartridge: (Wrong chip, encoder wheel combination, or

bad chip). If this happens immediately upon cartridge instillation,

there is either a bad contact to the chip, or the chip is bad. If the

machine cycles and then the message appears, the wrong encoder wheel is

installed. In the T632 machines, this message will also show if the extra

high yield cartridge is not installed. |

| 80 |

Scheduled maintenance (300,000 page) |

| 88 |

Toner Low |

| 200-280 |

Various paper jams |

Printer menu:

Press the “MENU” key until

“Utilities Menu” is displayed

Press “SELECT”

Press the “MENU” key until “Print Menu” is displayed

Press “SELECT” w:

Font Sample:

Press the “MENU” key until

“Utilities Menu” is displayed

Press “SELECT”

Press the “MENU” key until “Print Fonts” is displayed

Press “SELECT”

Select either the PCL fonts or the Postscript fonts,

Press “SELECT”

The Print Menu page contains

the printer page count, toner level, cartridge serial number, cartridge size,

if it is Prebate or not, and the cartridge type, (Normal, MICR, Label).

Press the “MENU” key until

“Quality Menu” is displayed

Press “SELECT”

Press the “MENU” key until

“Toner darkness” is displayed

Press “SELECT”

Choose a number between 1

and 10. “8” is the default setting

Press the “MENU” key until

“Quality Menu” is displayed

Press “SELECT”

Press the “MENU” key until

“Print Resolution” is displayed

Press “SELECT”

The options available are

300, 600, 1200 Image Q, and 1200 Dpi. The 1200 Image Q is for bitmapped

pictures. The printer default is 600 Dpi.

© 2003 Summit Laser Products, Inc. Any attempt to reproduce any part of

these instructions without the written consent of Summit Laser Products, Inc is

prohibited. All registered trademarks are the property of their respective

owners.

Contact Summit Laser Products

Toll Free Orders:

800-221-3516

Toll Free Fax: 888-791-9188

International Orders:

+1-631-218-8376

International Fax: +1-631-218-3285

Domestic Sales E-mail: sales@summitlaser.com

International Sales E-mail: export@summitlaser.com

Technical Support:

+1-631-218-8376

Technical Support E-Mail: tech@summitlaser.com

Mail: Summit

Laser Products

95 Orville Drive, Bohemia, New York 11716 - USA

Please report any broken links to:

webmaster@summitlaser.com

Authorized Summit Laser Distributors

All products on this web site, unless stated otherwise, are independently produced and distributed by Summit Laser, and not by the individual manufacturers of the copiers and printers referenced herein. Use of trade styles and trademarks of the individual manufacturers of the copiers and printers referenced herein are for descriptive purposes only and are not intended to imply any form of endorsement by the individual manufacturers of the refill or supply products offered herein. As such, all items in this catalog are deemed to be construed as “for use in,” “for use with or compatible with,” whether or not stated for each individual item as opposed to the group of items.

|