| Home |

New Arrivals!

|

Company Info

|

Publications

|

Special Features

| Contact Us |

|

|

|

|

|

|

|

|

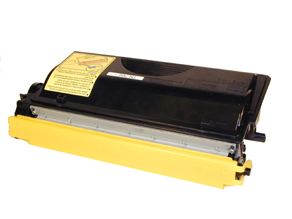

Brother TN-700 Toner Cartridges

DOC-0325

| Overview |

|

Released in November 2002, the Brother HL-7050 printer engine is the newest engine Brother has released to date. The TN-700 toner cartridges are loosely based on the TN-460/560 toner cartridges. These cartridges are very easy to do, but as with the TN-460 cartridges, most of the problems people experience when doing these cartridges stems from not understanding how they work. A few minutes now can save a lot of time (and money) later.

Before we get started, there is one major point about this cartridge that must be made. The TN-700 cartridge is different from all other brother cartridges to date in that it has a fuse that resets the printer. The fuse is located under the handle of the cartridge and must be replaced each cycle.

This cartridge system is different from Hp systems in a number of ways; the waste toner from the drum cartridge is recycled back into the toner supply chamber, the drum cartridge uses a cleaning felt (or brush) instead of a wiper blade or roller, and it also has both a Primary Corona Wire and a Transfer Roller. The Primary Corona wire has a built in cleaner that should be on the left side of the cartridge when not in use.

This engine is also unique in the sense that the developer roller in the toner cartridge actually touches the drum. There is not an air gap as in other cartridges. In other words, this engine does not use what is commonly known as "jumping technology" to transfer the image from the developer roller to the drum. This unusual fact doesn't change how the cartridge is recycled, but can lead to some interesting problems if BOTH the Toner and OPC cartridges are not cleaned properly. If you are to do these cartridges successfully, throw out any pre-conceived notions you may have based on other cartridges, and read the following carefully.

When an “empty” cartridge is returned for remanufacturing, the remaining toner (100g or so!) MUST be completely removed from the supply chamber before adding new toner. Failure to do this will cause back-grounding. In addition to contaminating the toner cartridge, this will also contaminate the cleaning section of the drum cartridge, which in turn will contaminate the toner cartridge again, (A vicious cycle!) The remaining 100g of toner is actually the waste toner, and a small amount of new toner combined. There is not enough new toner to work or “charge up” left. Not cleaning this toner completely out is the largest cause of cartridge failure!

The cleaning section of the drum cartridge consists of a "cleaning brush" and a recovery blade. The cleaning brush has two opposite charges placed on it during the print cycle. The first attracts any remaining toner off the drum. The second repels the toner off the brush back onto the drum where it then transfers back into the toner cartridge. This is all done in a timing sequence that does not interfere with the printing process. If the cleaning brush becomes contaminated with bad toner that will not accept the proper charge, the brush will not be able to clean itself, and back grounding will occur. It seems to be the nature of contaminated toner that it will accept most of the charge to be cleaned off the drum, but it will not accept the charge that would allow the brush to clean itself off at all. A properly working cleaning brush will at any given time have only a small amount of toner on it. Once contaminated, toner will accumulate, which will only cause the problems to get worse. The drum cartridge does not have a waste chamber; all the waste toner is recycled back into the toner cartridge.

Since the developer roller actually contacts the drum, the waste toner is transferred back into the supply of the toner cartridge. As stated above, once you print with a bad toner cartridge the drum unit will become contaminated. Even when you change out the toner with a good properly recycled or new OEM cartridge, the drum unit will transfer some of the bad toner back into the good toner cartridge, which will again cause back grounding. Both cartridges will be contaminated again. Basically, once you have back-grounding, both cartridges need to be cleaned out.

The remaining 100g or so of "toner" in the toner cartridge is just below the bare minimum that can maintain the proper charge level. When the change toner light comes on, the toner will not charge up to the proper level and will cause the back grounding. As the toner cartridge reaches the end of its useful life, the printer senses the low charge level in the toner supply and will try to keep the charge level up. This constant charging keeps an almost "empty" cartridge from back grounding. Once the printer cannot get the remaining toner up to the minimum charge, the change toner light comes on. The cartridge at this point will still be printing properly. If you were to take that same cartridge out of the machine for a few days, and then put it back in the printer with out doing anything to it, the cartridge will background. This will happen because the charge level that the printer was trying so hard to keep up has dissipated out and the materials left can no longer accept a proper charge.

What does this all mean?

Make sure that your cartridge techs thoroughly clean out the supply chamber of the toner cartridge. Clean dry compressed air is the best method.

In the event that they forget, and you have a back-grounding cartridge. The toner must be completely cleaned out again. (Do not use the toner over!!) and NEW fresh toner MUST be installed. At this point, the drum unit has to be taken apart and cleaned out with emphasis on the cleaning brush area. This is a very simple process but very necessary once contaminated.

At this point in time, Brother has only released the TN-700 cartridge which is rated for 12,000 pages at 5% coverage. The printer itself is rated for 30ppm with a max density of 1200dpi.

| Required Tools |

|

Toner approved vacuum

Phillips Head Screwdriver

Small Common Screwdriver

Needle nose pliers

| Materials Needed |

|

Brother 7050 Black Toner 345g

Replacement fuse 1/8A 250V fast acting (Required)

Developer Roller Cover

Alcohol

High quality double sided tape

Lint free cotton cloths

Toner magnet cloths

White Lithium Grease

| Disassembly |

|

Vacuum the exterior of the toner cartridge. Be careful of the drum!

Place the cartridge on the bench drum side up (Label face down), with the toner supply towards you.

With a spring hook, remove the two springs from each end of the cartridge. See Figure 7

Vacuum the exterior of the cartridge.

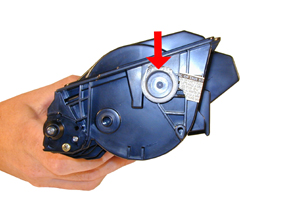

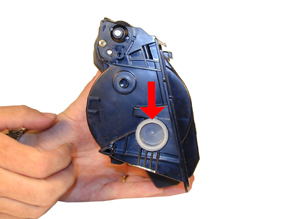

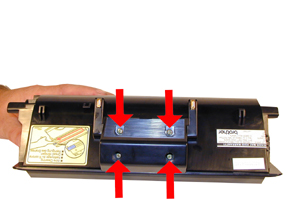

Remove the fill plug from the toner cartridge. Dump the remaining toner into the garbage, and vacuum clean. See Figure 1

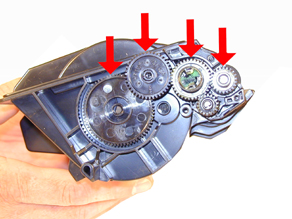

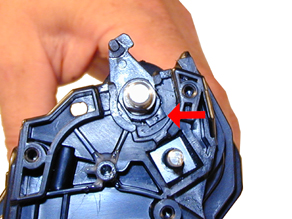

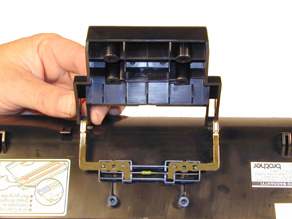

On the GEAR side of the static roller, remove the three screws and end cap. See Figure 2

Note the grease on the gears and gear shaft. This grease is extremely important, and must be replaced if it has become contaminated with toner

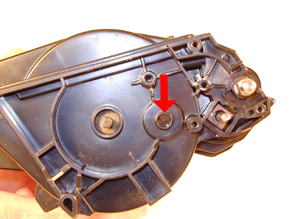

Remove the four loose gears from the cartridge. See Figure 3

Remove the black bushing, e-ring and small gear. See Figure’s 4 & 5

FIGURE 1

FIGURE 2

FIGURE 3

FIGURE 4

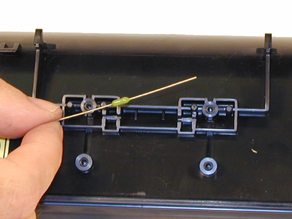

On the doctor blade side of the static roller, there is another small plate that is located on the end of the roller and inside the plastic wall of the cartridge. From the outside of the wall locate a small round hole. Press in the round tab located inside the hole. While pressing in turn the plate up so that the plate and roller are free. See Figure's 6 & 7

Remove the static roller assembly. See Figure 8

FIGURE 5

FIGURE 6

FIGURE 7

FIGURE 8

Carefully lift up the developer roller sealing felt from the Dr. blade edges. Be very careful not to damage the felt seals. See Figure 9

Remove the two screws and the Dr. Blade. Vacuum or blow out all the remaining toner from the hopper. Be especially careful to get all the toner from the feed roller. See Figure 10

Replace the Dr. Blade and the two screws. Re-attach the developer sealing felt to the blade. If the felt is not sticking properly, clean the glue with a small amount of alcohol. If the still doesn’t work use a new piece of double sided tape. See Figure 11

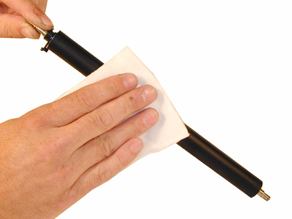

Clean the static roller with a lint free cloth. Do not use any chemicals to clean the roller. A dry clean cloth will work fine. See Figure 12

FIGURE 9

FIGURE 10

FIGURE 11

FIGURE 12

Re-install the static roller, inside end plate first. Turn the inside plate so that it locks in place. Make sure that the small tab on the locking plate fits over the side wall of the cartridge. See Figure's 13 & 14

Clean the gears, making sure that the fine toothed gears have no toner on them. This is a good time to also check the gear shafts to make sure there is enough grease. If the shafts appear dry, or the grease is contaminated with toner, clean the shaft and inside of the gear. Replace the grease with white lithium grease. See Figure 15

Clean the optical sensor windows located on each side of the cartridge. If these windows are dirty, the toner low functions will be impaired. See Figure 16

FIGURE 13

FIGURE 14

FIGURE 15

FIGURE 16

Install the four loose gears. See Figure 17

Install the developer roller gear, and E-ring. Make sure all the other gears are meshing properly. See Figure 18

Install the gear cover plate, and three screws. If the gear plate does not fit flat, the large gear is upside down. See Figure 19

Fill the cartridge with 345g brother 700 toner. See Figure 20

FIGURE 17

FIGURE 18

FIGURE 19

FIGURE 20

Replace the fill plug. See Figure 21

Wipe the cartridge down to remove any remaining toner dust.

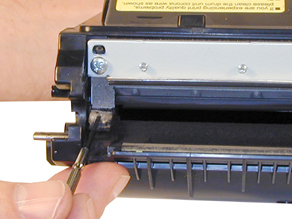

Remove the four screws from the back handle. See Figure 22

Carefully pry off the handle from the cartridge. See Figure 23

On each side there is a metal contact plate. Remove both plates. See Figure 24

FIGURE 21

FIGURE 22

FIGURE 23

FIGURE 24

Replace the fuse. See Figure 25

Replace the two metal contact plates, plastic handle, and the four screws.

Install the Developer Roller cover. This cover is very important in that the developer roller is exposed and very easily damaged. See Figure 26

FIGURE 25

FIGURE 26

| RUNNING TEST PAGES |

|

Press the MENU button until “Information” appears on the display.

Press the SET button.

Press the +/- button the get the desired page. The pages available are the Settings Page, Test Page, Demo page, Font Page, Cleaning Page.

Press the SET button.

| CHANGING THE PRINTER DENSITY |

|

Press the MENU button until “Quality” appears on the display.

Press the SET button.

Press the +/- button until “Density” appears on the display.

Press the SET button.

Press the +/- button until the desired number appears on the display.

Press the SET button.

| Error Messages |

|

Most of the error messages are in plain English and there is no need to cover them here. There is one new message however that needs to be clarified.

As the toner gets low, a “TONER LOW” message appears. Brother does not list when this message will first appear. The next message to appear is: “TONER LIFE END” message. According to the Brother manual, there are two conditions where this message will be displayed. The first is when the cartridge is out of new toner. The second is where is when the “Mechanical Components” of the cartridge have reached the end of their life. Near as I can tell, if you print with very low coverage, and still have fresh toner left when the cartridge page count reaches 12,000, the printer will stop printing until the cartridge is replaced. Apparently the fuse is resetting the page counter of the cartridge, “Toner Life End” will appear when the page count is up, or when the toner level is low, which ever comes first.

Although we are still running tests, this may actually be a good thing. Since the waste toner is returned and mixed with the new toner, some users would keep shaking the cartridge, keeping the machine on to squeeze every last bit of toner out. These same people would then complain that their drum unit was then backgrounding. This feature I think will eliminate that from happening.

© 2003 Summit Laser Products, Inc. Any attempt to reproduce any part of these instructions without the written consent of Summit Laser Products, Inc is prohibited. All registered trademarks are the property of their respective owners.

Contact Summit Laser Products

Toll Free Orders: 800-221-3516

Toll Free Fax: 888-791-9188International Orders: +1-631-218-8376

International Fax: +1-631-218-3285Domestic Sales E-mail: sales@summitlaser.com

International Sales E-mail: export@summitlaser.comTechnical Support: +1-631-218-8376

Technical Support E-Mail: tech@summitlaser.comMail: Summit Laser Products

95 Orville Drive, Bohemia, New York 11716 - USAPlease report any broken links to: webmaster@summitlaser.com

Authorized Summit Laser Distributors

| Ukraine

Distributor SINT Company order@sint-master.com

|

All products on this web site, unless stated otherwise, are independently produced and distributed by Summit Laser, and not by the individual manufacturers of the copiers and printers referenced herein. Use of trade styles and trademarks of the individual manufacturers of the copiers and printers referenced herein are for descriptive purposes only and are not intended to imply any form of endorsement by the individual manufacturers of the refill or supply products offered herein. As such, all items in this catalog are deemed to be construed as “for use in,” “for use with or compatible with,” whether or not stated for each individual item as opposed to the group of items.