| Home |

New Arrivals!

|

Company Info

|

Publications

|

Special Features

| Contact Us |

|

|

|

|

|

|

|

|

Samsung SCX-4216 Toner Cartridges

DOC-0326

| Overview | |

First released in June 2003, Samsung SCX-4216 fax machines are based on one of Samsung’s newest engines. The SCX-4216 series runs at 16 ppm with a maximum resolution of 600 dpi.

The machines currently based on this engine, are the SCX-4016, SCX-4116, and the SCX-4216F. All three of these machines have a Toner Save function that is easily accessed by the Toner Save button on the control panel. In other words, your customers may accidentally turn it on, and not realize it! If the button is lit up, the toner save function is on. The feed rollers, transfer roller, and fuser assy. are all rated for 60,000 pages.

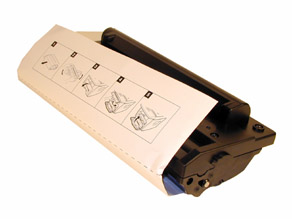

The SCX-4216D3 cartridge looks similar in style as the SF-5100, but is different enough to warrant its own separate instruction. Unlike some of the other newer Samsung engines, this cartridge will not fit in a modified E210 machine. Figures 1 & 2 give a better look at this cartridge. The drum, rollers, and blades are all unique to this cartridge. If a cartridge is installed in a machine with a blown fuse, and toner low was already reached, the message “Invalid cartridge” will appear on the display, and the machine will not print. The fuse has to be replaced each cycle.

FIGURE 1 |

FIGURE 2 |

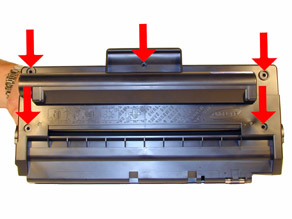

These cartridges do not have a drum cover, and come new with a piece of heavy paper taped around the cartridge. (See Figure 3) The SF-4216 also does not use a seal. All new cartridges opened so far have shown some toner leakage on the drum that would have shown on any prints.

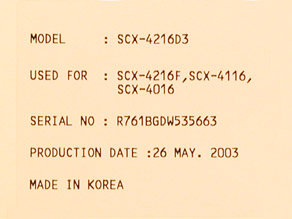

The standard cartridge (Samsung part# SCX-4216D3) comes new with 90g toner, and is rated for 3,000 pages at 5% coverage. If you look at the cartridge, it appears that Samsung has discovered our industry, the top of the cartridge is embossed with Samsung all over it. Samsung cartridges also all now come with a card that states the cartridge is a genuine Samsung. This card also gives the Model #, Serial #, and Production date. See Figure’s 4 & 5

FIGURE 3 |

FIGURE 4 |

FIGURE 5 |

|

| Required Tools | |

- Toner approved vacuum.

- Small Common screw driver

- Phillips head screwdriver

- Needle nose pliers

| Required Supplies | |

- 90g Toner

- Fuse: 63mA, 250V, 5x20mm, fast-acting glass type

- Conductive Grease

- Drum lubricating powder

| Disassembly | |

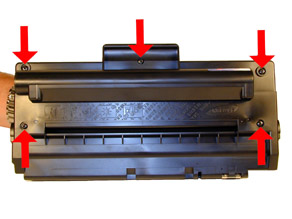

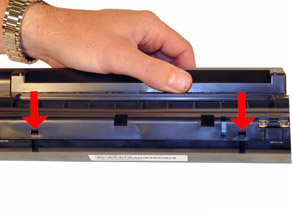

- Place the cartridge with the handle facing up. Remove the 5 top

cover screws. See Figure 6

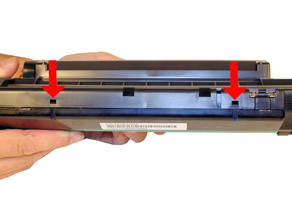

- Underneath the handle of the cartridge to the right and left, there are 2 plastic tabs GENTLY press them in, and lift that side of the cover up. See Figure 7

FIGURE 6 |

FIGURE 7 |

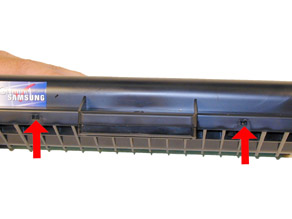

- On the front edge of the cartridge, there are two more tabs. Press

these two tabs in, and lift the cover off. See Figure 8

CAUTION: The upper half of the toner hopper is being removed. If there is a lot of toner left in the hopper, it can dump out all over! Vacuum the hopper clean.

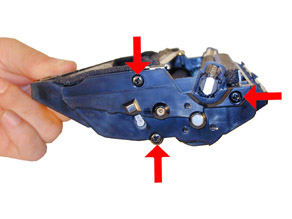

- With the toner hopper away from you, remove the three screws on the left side end cap. Remove the end cap. See Figure 9

FIGURE 8 |

FIGURE 9 |

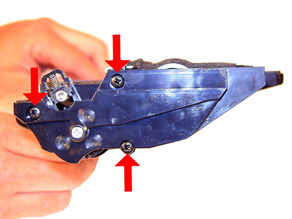

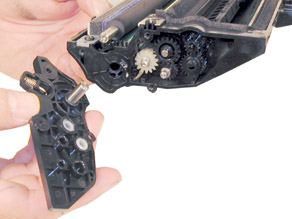

- Remove the three screws on the right side end cap. Remove the end

cap. See Figure’s 10 & 11

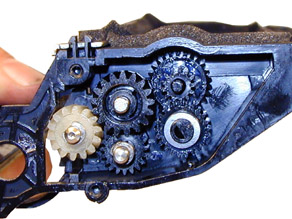

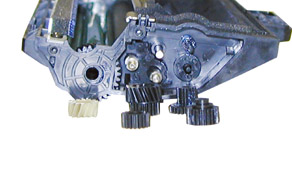

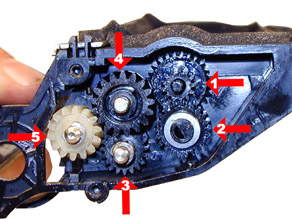

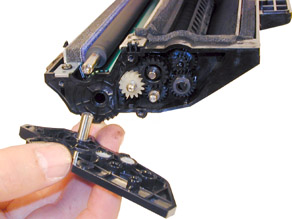

- Also on the right side there is a series of gears under the end cap. Make a note of the location of each gear, and remove them. See Figure’s 12 & 13

FIGURE 10 |

FIGURE 11 |

FIGURE 12 |

FIGURE 13 |

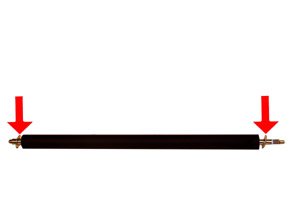

- Remove the PCR. See Figure 14

- Clean the PCR with your normal PCR cleaner.

WARNING: Do not clean the OEM PCR with alcohol, as this will remove the conductive coating from the roller. If the PCR is an aftermarket, follow the cleaning methods recommended by the manufacturer. If the PCR is an OEM, we recommend it be cleaned with your standard PCR cleaner.

- There are 2 screws on the PCR cleaner Assy. Remove them and gently

pry the blade up. Note that there are not any alignment tabs or posts

to worry about. This PCR cleaner also has what can be considered a

wiper blade. It is a very flimsy blade attached to the metal bar.

Wipe this blade down with a clean lint free cloth before re-installing.

See Figures 15 & 16

- It is very important that the PCR cleaner be cleaned.

Vacuum or blow off any residual toner from the foam/felt.

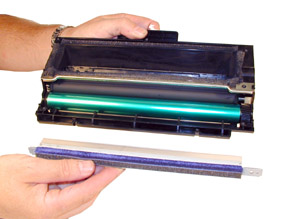

- With the PCR Cleaner Assembly removed, the drum can easily be removed by lifting it out. See Figure 17

FIGURE 14 |

FIGURE 15 |

FIGURE 16 |

FIGURE 17 |

- Clean out any remaining toner from the cartridge.

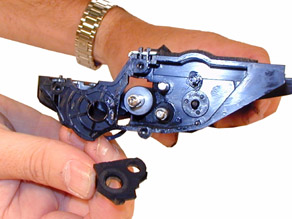

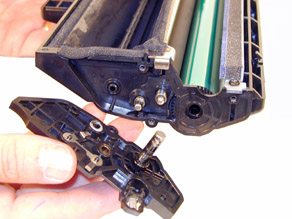

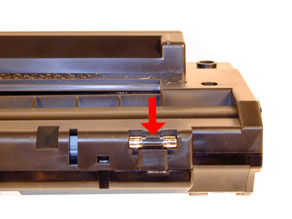

- Press in on the bottom tab of the Developer roller plate (Right

Side) to release it. See Figure 18

- Slide the entire plate towards the edge of the developer roller

cavity, and lift up. The Plate should come loose. See Figure 19

- Gently pry out the roller plate from the cartridge. The foam seal,

and plastic flat washer will come out with it. Be careful not to damage

the foam seal, or loose the flat washer. See Figure 20

- Remove the Developer Roller. Be careful not to damage or lose the flat washers on the roller. See Figure 21

FIGURE 18 |

FIGURE 19 |

FIGURE 20 |

FIGURE 21 |

- It is highly recommended that the Doctor Blade be cleaned. Failure

to do so will cause streaking. The Doctor Blade can be cleaned with

out removing it. Dampen a cotton swab with alcohol, and clean the

blade. Be careful not to press too hard and damage the blade. If the

blade has a heavy buildup of toner on it, clean it with Acetone, and

then alcohol. Removing the blade is difficult because of the foam

seals attached. If the seals are torn, the cartridge will leak. That

is why we do not recommend it. Once replacement Dr. Blades are available,

they will have to come with replacement foam. See Figure 22

- Replace the Developer roller, and flat washers. See Figure 23

- If no grease is left on the gears and gear shafts, or

it is contaminated with toner clean it all off. Replace it with white

lithium grease. Be sure to clean and grease the gear shafts, and inside

the gear.

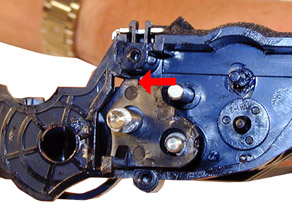

- Replace the roller plate and 5 gears. When installing the plate,

do the opposite of how it came out. Keep it towards the front edge

so that the small tab on top fits behind the wall of the cartridge.

Look carefully at the picture of the gears. Each gear must fit in

this exact way. The gears labeled in order of installation. See Figure

24

- Install the new drum in place. See Figure 25

FIGURE 22 |

FIGURE 23 |

FIGURE 24 |

FIGURE 25 |

- Install the PCR cleaner Assy. and two screws. See Figure 26

- Clean the conductive grease off the left side (Non Gear) end cap

and replace with fresh grease. Replace the end cap and three screws.

See Figure 27

- Install the PCR. See Figure 28

- Install the right side end cap, and screws. Make sure the PCR fits

correctly in its holder, and all the gears are aligned. See Figure

29

FIGURE 26 |

FIGURE 27 |

FIGURE 28 |

FIGURE 29 |

- Fill the hopper with 90g of the SF-5100 toner. See Figure 30

This can also be done through the fill plug, but the fill plug tends to leak and will probably have to be sealed with silicon.

- Carefully snap the cover on making sure all the tabs lock in place.

See Figure’s 31 & 32

- Install the five screws in the top cover. See Figure 33

- Replace the fuse on the top of the cartridge with a new 63mA fuse. Be careful not to break the plastic clamp. See Figure 34

FIGURE 30 |

FIGURE 31 |

FIGURE 32 |

FIGURE 33 |

FIGURE 34 |

|

| Running a Cleaning Page | |

The SCX-4216 has the ability to run its own cleaning page. This page according to Samsung will clean any toner particles off the drum that may be stuck there.

Press the MENU key on the front panel until “MAINTENANCE” appears.

Press the MENU key again until “CLEAN DRUM” shows on the display. (This is the first option in the Maintenance menu)

Press the ENTER key.

A Cleaning page will then print.

| Printing a Test Page | |

The best way to run test pages is simply to make a copy. Take a printed page with both text and graphics, and run a few copies.

| Cleaning the Machine | |

Other than the cartridge bay, the document feed rollers and scanner must also be cleaned.

Lift up the top cover. There is a white roller attached to the lid. Clean the roller with a soft lint free cloth and water. DO NOT use any chemicals on this roller!

In the center of the lid is the white Document Cover. Clean any marks off the cover.

The scanner glass is located to the left of the document glass on the 4116, and 4216F machines. Clean both with a soft lint free cloth. If stubborn dirt will not come off, dampen the cloth with water, and dry the glass. Be careful not to scratch the glass!

| Common Cartridge Problems | |

Even Light Prints: Check to see if the Toner Save button on the control panel is lit up. If so, press it so that the light goes off. This is very easy to press accidentally.

A Dirty or Bad Primary Charge Roller (PCR); located Inside the cartridge, this will show on the test print as vertical gray streaks down the page, as a gray background throughout the page, as ghosting where part of a previously printed area is repeated, or as a mark that repeats every 40mm.

Dirty PCR Connection; This will show as horizontal dark black bars across the page, or as shading throughout the page.

Scratched Drum; This is shown by a very thin, perfectly straight line that runs from the top to the bottom of the test page.

Chipped Drum; This will show as a dot or series of dots that repeat every 78mm.

Light Damaged Drum; This will show up as a shaded area on the test print that should be white. Again this will repeat every 78mm.

Bad Wiper Blade; This will show as either a gray line approximately 1/8" thick, or as shading across the entire page. In either case there will be a film of toner on the drum surface.

Bad Developer Roller; This will show up as light print or as a mark that repeats every 45mm

| Machine Error Codes | |

As with most of the newer Samsung models, the error codes are all in English and are self-explanatory. The biggest problems you will run into are paper jams, and a dirty scanner. Keeping the machine clean with periodic maintenance will take care of most of them.

© 2003 Summit Laser Products, Inc. Any attempt to reproduce any part of these instructions without the written consent of Summit Laser Products, Inc is prohibited. All registered trademarks are the property of their respective owners.

Contact Summit Laser Products

Toll Free Orders: 800-221-3516

Toll Free Fax: 888-791-9188International Orders: +1-631-218-8376

International Fax: +1-631-218-3285Domestic Sales E-mail: sales@summitlaser.com

International Sales E-mail: export@summitlaser.comTechnical Support: +1-631-218-8376

Technical Support E-Mail: tech@summitlaser.comMail: Summit Laser Products

95 Orville Drive, Bohemia, New York 11716 - USAPlease report any broken links to: webmaster@summitlaser.com

Authorized Summit Laser Distributors

| Ukraine

Distributor SINT Company order@sint-master.com

|

All products on this web site, unless stated otherwise, are independently produced and distributed by Summit Laser, and not by the individual manufacturers of the copiers and printers referenced herein. Use of trade styles and trademarks of the individual manufacturers of the copiers and printers referenced herein are for descriptive purposes only and are not intended to imply any form of endorsement by the individual manufacturers of the refill or supply products offered herein. As such, all items in this catalog are deemed to be construed as “for use in,” “for use with or compatible with,” whether or not stated for each individual item as opposed to the group of items.