| Home |

New Arrivals!

|

Company Info

|

Publications

|

Special Features

| Contact Us |

|

|

|

|

|

|

|

|

Samsung ML-2150 Toner Cartridges

DOC-0329

| Overview | |

The Samsung ML-2150 series of printers are based on a Samsung 21 ppm, 1200 dpi engine. These cartridges from the outside seem to be a beefed up version of the P8e. From the inside however, they are completely different.

Unfortunately with this cartridge (ML-2150D8/XAA), Samsung has joined the Dark Side, and now uses a chip. Testing is still ongoing, but the early indications are that the chip is a cross between HP and Lexmark. The chip controls all the toner low functions (HP) as well as eventually shutting the cartridge down (Lexmark). In our tests so far, both the starter and the standard cartridge can be refilled twice*. After that, the display on the printer states to change the cartridge. Only one page at a time will print from that point. Toner low shows the entire time, but the printer prints normally. The starter cartridge is rated for 4K pages, while the Standard cartridge is rated for 8K pages. We are just starting to evaluate the code on this chip so we do not know if the chip is page count driven or not.

*For our initial tests, we put in 90g to match the OEM 4K cartridge, and 160g in the standard 8K cartridge. If you put in the full 160g in a starter, the chip in all likely hood will only last one cycle. Standard cartridge chips so far have printed roughly 2 1/2 cycles (22,000 pages) not counting the OEM cycle before the chip stopped. The Starter cartridge ran for just under 12,000 pages (not counting the OEM) before the chip stopped.

We are actively working on a chip solution for this (Sept. 2003), and will hopefully have it available as you read this.

Other than the chip, I really like these machines. With speeds of 21ppm, and the base printer selling for $370.00, they are selling very quickly. The cartridge lists for $179.99 so there is plenty of room for a decent profit.

| Required Tools | |

- Toner approved vacuum.

- A small Common screw driver

- #1 Phillips head screwdriver

- Needle nose pliers

- Spring Hook

| Required Supplies | |

- ML-2150 toner, 160g (For 8k cartridge)

- iper Blade (Check for availability)

- OPC Drum (Check for availability)

- Kynar padding powder

- PCR Cleaner

- Conductive grease

| Disassembly | |

- Clean the exterior of the cartridge.

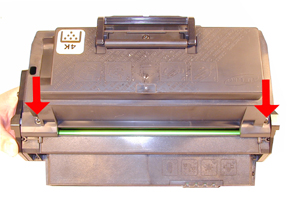

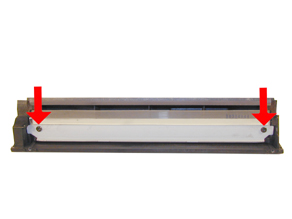

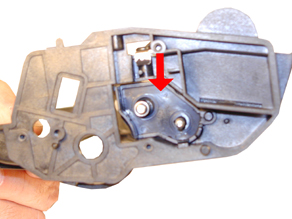

- Place the cartridge with the handle facing up. Remove the top 2

screws. See Figure

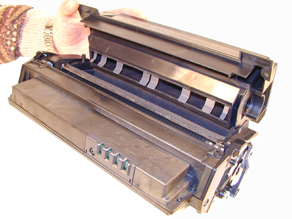

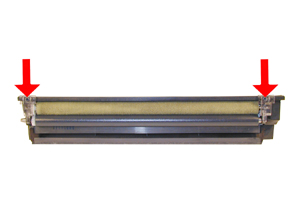

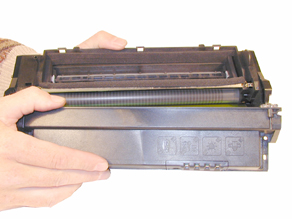

- Tilt the hopper away from the screw holes and remove. Vacuum both the hopper and cartridge clean. See Figure 2

FIGURE 1 |

FIGURE 2 |

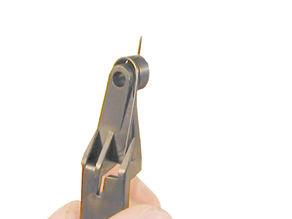

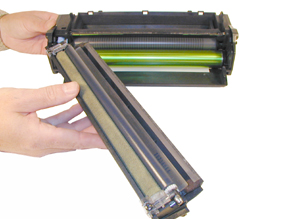

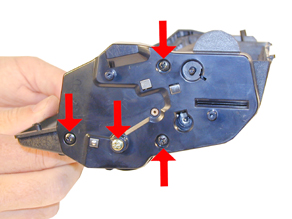

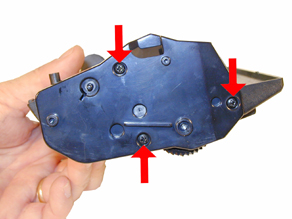

- Locate both the drum cover arms and gently pry them off. Try to

keep the springs on the arms to make re-assembly easier later. See

Figures 3 & 4

FIGURE 3 |

FIGURE 4 |

- Remove the two screws on the Waste chamber. Lift the waste chamber

off the cartridge. See Figure 5 & 6

- On the waste chamber, remove the two screws on the PCR clips. Remove

the clips, and the PCR/PCR Cleaner. This cartridge also has a built

in PCR Cleaner. Make sure you note the orientation of the PCR as each

side is different. See Figure’s 7 & 8

FIGURE 5 |

FIGURE 6 |

FIGURE 7 |

FIGURE 8 |

- Remove the two screws on the wiper blade. Remove the blade. Figure

9

- Clean out the Waste chamber.

NOTE: Be very careful not to damage or distort the thin Mylar Recovery Blade next to the wiper blade. If this blade is bent or damaged in any way, it should be replaced

9) Clean the PCR and PCR Cleaner. The PCR Cleaner should only be cleaned with clean dry compressed air, or Vacuuming. No chemicals should be used.WARNING: Do not clean the OEM PCR with alcohol as this will remove the conductive coating on the roller. IF the PCR is an after market, follow the cleaning methods recommended by the manufacturer. If the PCR is an OEM, we recommended it be cleaned with your standard PCR cleaner

10) Re-install the Wiper Blade. New blades are at the time of this writing not available, but the OEM will easily last another cycle.

-

Reinstall the PCR/PCR Cleaner, clips, and screws. Put the entire assy. aside. See Figure 10

-

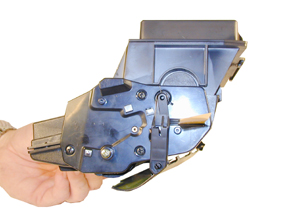

Remove the Four screws on the right side end cap. The fourth brass colored screw is a machine threaded screw that holds the drum axle in place. Remove the end cap. If the gold colored screw spins, press in on the drum gear, and the screw will come loose. See Figure 11.

-

Remove the three screws on the left side end cap. Remove the end cap. See Figure 12.

FIGURE 9 |

FIGURE 10 |

FIGURE 11 |

FIGURE 12 |

- Remove the Metal plate and gear assy. Make sure to note the orientation

of the remaining gears as they are now loose, a small drive belt will

come loose. Remove the gears. See Figure 13

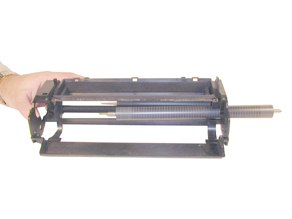

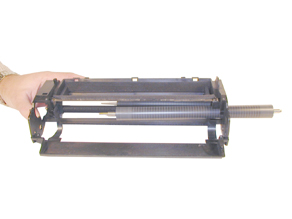

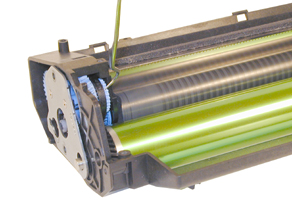

15) From the large gear side, push the axle in and remove it from the opposite side. Remove the drum. See Figure 14.

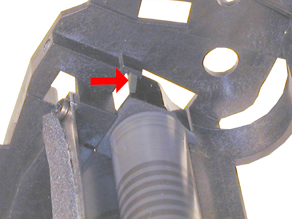

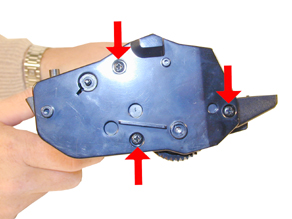

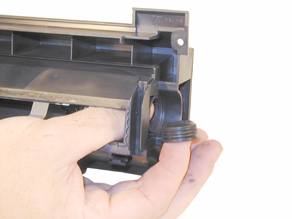

- Press in on the 2 small tabs of the developer roller plate on the

right side. See Figure’s 15 & 16.

FIGURE 13 |

FIGURE 14 |

FIGURE 15 |

FIGURE 16 |

- Remove the developer roller. If there is a built up on the roller,

clean it with a good quality rubber roller cleaner that does not leave

any residue. Be careful not to damage the two flat shims on either

side of the roller. See Figure 17

- Clean the toner feed roller with clean compressed air. See Figure

18

- Clean the Dr. Blade with a cotton swab and 99% pure isopropyl alcohol.

It is best not to remove this blade as the foam seal on top tends

to tear, and will then leak. See Figure 19

- Re-install the developer roller long shaft side to the left or gear

side of the cartridge. See Figure 20

FIGURE 17 |

FIGURE 18 |

FIGURE 19 |

FIGURE 20 |

- Install the developer roller plate. Make sure both tabs lock into

place. See Figure 21

- Install the drum and drum axle. Slide the axle in from the small

gear side, making sure that the threaded hole is on the right (small

gear) side. See Figure 22

- Install the right end cap and four screws. See Figure 23

- Install the gears on the left side, place the belt over the top

right gear. See Figure 24

FIGURE 21 |

FIGURE 22 |

FIGURE 23 |

FIGURE 24 |

- Install the gear plate and two gears. With the spring hook, pull

the belt over the top gear. See Figure 25

- Install the end cap and three screws. See Figure 26

- Re-install the waste chamber and screws. See Figure 27.

- Push the fill plug out from the inside of the supply hopper. Removing

it this way will prevent any damage to the plug. (You will need small

fingers for this!) See Figure 28

FIGURE 25 |

FIGURE 26 |

FIGURE 27 |

FIGURE 28 |

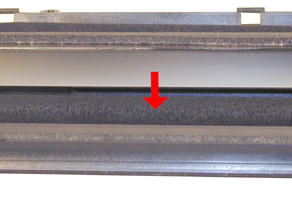

- Install the seal on the toner hopper. Make sure the seal tab is

orientated as shown. See Figure 29

- Fill the supply hopper with 190g 2150 toner. See Figure 30

- Slide the seal pull tab under the foam seal and out the cartridge

wall. See Figure 31

- Install the toner hopper. Place it at an angle so that the back

edge tabs fit into their slots. Install the two front screws. See

Figure’s 32 & 33

FIGURE 29 |

FIGURE 30 |

FIGURE 31 |

FIGURE 32 |

- Install the drum cover loosely so that the arms are on the posts.

With the spring hook, pull the spring tab into the slot in the end cap

to set the spring tension. See Figure’s 34 & 35

- Once new replacement chips are available, replace the chip. See Figure 36

FIGURE 33 |

FIGURE 34 |

FIGURE 35 |

FIGURE 36 |

| Common Cartridge Problems | |

A Dirty or Bad Primary Charge Roller (PCR); located Inside the cartridge, this will show on the test print as vertical gray streaks down the page, as a gray background throughout the page, or as ghosting where part of a previously printed area is repeated. Dirty PCR Connection; This will show as horizontal dark black bars across the page, or as shading throughout the page.

Scratched Drum; this is shown by a very thin, perfectly straight line that runs from the top to the bottom of the test page.

Chipped Drum; This will show as a dot or series of dots that repeat 3 times per page. Any drum defects will repeat 3 times per page.

Light Damaged Drum; This will show up as a shaded area on the test print that should be white. Again this will repeat 3 times per page.

Bad Wiper Blade; This will show as either a gray line approximately 1/8" thick, or as shading across the entire page. In either case there will be a film of toner on the drum surface.

Light print overall: Check to see if the toner save mode is on.

| Printing Test Pages | |

CONFIGURATION PAGE

Press the “MENU” button on the control panel until “Information” appears on the display.

Press the “Enter” button

Press the “Scroll” button until “Configuration” appears on the display

Press the Enter button.

A Configuration page will print outDEMO PAGE

Press the “MENU” button on the control panel until “Information” appears on the display.

Press the “Enter” button

Press the “Scroll” button until “DEMO PAGE” appears on the display

Press the Enter button.

A DEMO page will print out.

| Printing a Cleaning Page: | |

Two cleaning pages are available. One for the fuser or one for the drum in the cartridge. According to the Samsung manual, the drum cleaning page will clean up dust, and the fuser toner. How the user is supposed to know the difference, I have no idea. If you are instructing your customer to run a cleaning page, I would have them run both.

Press the “MENU” button on the control panel until “Setup” appears on the display.

Press the “Enter” button

Press the “Scroll” button until “Maintenance” appears on the bottom line of the display

Press the “Enter” button

Press the “Scroll” button until either “OPC Cleaning”, or “Fuser Cleaning” appears on the display

Press the “Enter” Button

| Printer Error Codes | |

Like most other Samsung machines, all error messages are text based, and self explanatory.

© 2003 Summit Laser Products, Inc. Any attempt to reproduce any part of these instructions without the written consent of Summit Laser Products, Inc is prohibited. All registered trademarks are the property of their respective owners.

Contact Summit Laser Products

Toll Free Orders: 800-221-3516

Toll Free Fax: 888-791-9188International Orders: +1-631-218-8376

International Fax: +1-631-218-3285Domestic Sales E-mail: sales@summitlaser.com

International Sales E-mail: export@summitlaser.comTechnical Support: +1-631-218-8376

Technical Support E-Mail: tech@summitlaser.comMail: Summit Laser Products

95 Orville Drive, Bohemia, New York 11716 - USAPlease report any broken links to: webmaster@summitlaser.com

Authorized Summit Laser Distributors

| Ukraine

Distributor SINT Company order@sint-master.com

|

All products on this web site, unless stated otherwise, are independently produced and distributed by Summit Laser, and not by the individual manufacturers of the copiers and printers referenced herein. Use of trade styles and trademarks of the individual manufacturers of the copiers and printers referenced herein are for descriptive purposes only and are not intended to imply any form of endorsement by the individual manufacturers of the refill or supply products offered herein. As such, all items in this catalog are deemed to be construed as “for use in,” “for use with or compatible with,” whether or not stated for each individual item as opposed to the group of items.