|

Remanufacturing the HP

LJ-1012 Toner Cartridges

DOC-0334

In September 2003, Hewlett Packard released the

LaserJet 1012 printer. The HP-1012 series of laser printers are based

on a 15 ppm, 1200dpi Canon engine. As with the 1150 cartridge, this

cartridge does not have a chip! There is not even a location for one!

The Q2612A is rated for 2,000 pages. Physically, the cartridges look

like a cross between the 1200 (15X) and the AX/1100.

The pin system holding the two halves of the cartridge together is similar

to the HP-1200. One method of removing them is to cut two small holes in the

top to get access to the pins. The hole location on these cartridges is almost

identical to the 1200, and the same methods you use for the 1200 should work

here. Another easier method is to bend out the drum guard, remove the drum

and push the pins out from the inside. The draw back to this method is that

if you bend out the guard too much, it will break, and the cartridge is shot.

The magnetic roller has a very thin copper spring as a contact. Although

in our testing so far the spring has held up, we are concerned that over time

it will get weak and cause a contact issue.

HP has changed their packaging with these cartridges. Figure A shows the

new protective insert. Basically it is a formed, very stiff bubble wrap insert.

We tossed it around here to see if we could damage the cartridge, we couldn’t.

FIGURE

A FIGURE

A

With the 1012 having a street price of $199.00 (as of October 2003), these

machines are going to be very popular. If you are looking to get a test machine,

just know that only the 1015 has a parallel port. The 1010 and 1012 have a

USB port only. For those machines, if you are using full black and full gray

pages, you will have to print them from a computer. (Excell is an easy way

to create them). All three machines also have a very small foot print. They

are being advertised by HP as the perfect printer for a crowded workspace,

(personal printer for corporate execs. Etc.).

The 1010 runs at 12ppm, with a max DPI of 600 (this is with Ret). The 1012,

and 1015 machines run at 15ppm, with a max DPI of 1200 (using Ret). The 1010,

and 1012 both come with 8MB RAM, where the 1015 comes with 16MB RAM. As stated

above, only the 1015 has a parallel port. The 1010 and 1012 have a USB port

only (USB 2.0). All three list the first page out in 8 seconds. We have sent

some fairly complicated pages to our 1012, and 8 seconds is a fair estimate.

Cartridge troubleshooting as well as running test pages, cleaning pages and

some simple printer troubleshooting will be covered at the end of this article.

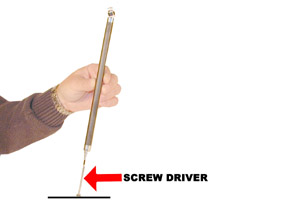

- Phillips head screw driver.

- Small Common screw driver

- Dremel type tool with side grinding bit

- Spring Hook

- Jewelers Screwdriver set

-

150g HP-1012 toner,

(Unique to this series!) for the Q2612A cartridge (2500 pages)

-

New Drum (Unique to this series)

-

Wiper Blade (Unique to this series)

-

Dr. Blade (Unique to this series)

-

Magnetic roller (Unique to this series)

-

Sealing Strip (HP-1200)

-

Cotton Swabs

-

Isopropyl Alcohol

-

Drum Padding Powder

-

Conductive Grease

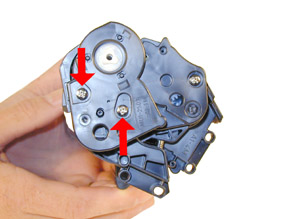

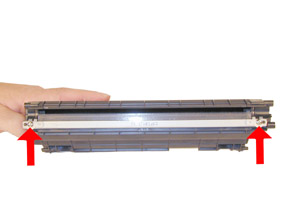

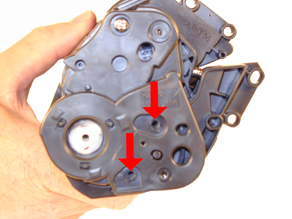

1) Remove the Right side end cap from the cartridge and the two screws. See

Figure 1

The pins in these cartridges are very similar to the HP-1200 cartridge. One

way to remove them is to cut two small holes in basically the same area as

the 1200. This method is covered in steps 2-3. The alternative method is covered

in steps 4-8.

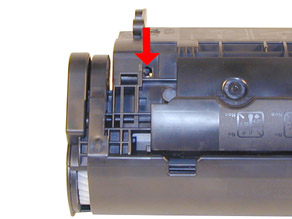

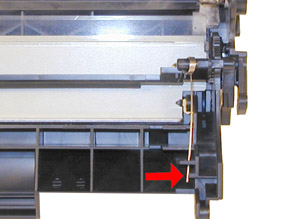

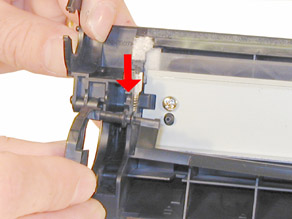

2) Drill a shallow hole on each side of the cartridge as indicated by Figures’

2, 3, & 4.

FIGURE 1

|

FIGURE 2

|

| |

|

FIGURE 3

|

FIGURE 4

|

3) Push the pins out with a modified Allen wrench, or a modified spring hook.

See Figures 5 & 6

Steps 4-8 are the alternative method of opening the cartridge. Although it

is easier and faster, you must be careful not to bend the drum guard too far

out or it will break, making the cartridge useless.

4) Bend the drum guard carefully away from the drum. See Figure 7

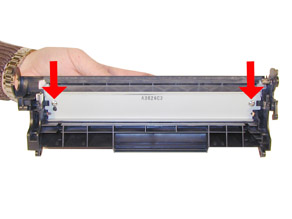

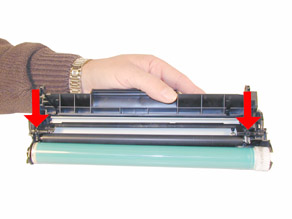

5) While holding the guard away from the drum, grasp the drum by the large

gear, and carefully work it out of the cartridge. See Figure 8

FIGURE 5

|

FIGURE 6

|

| |

|

FIGURE 7

|

FIGURE 8

|

6) Remove the PCR and clean with your standard PCR cleaner. We have been using

Nu-Finish for years with out any problems. See Figure 9

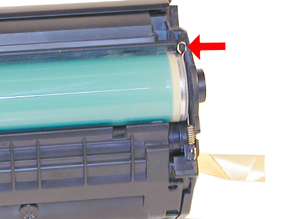

7) Remove the small spring that keeps the tension between the two halves.

This spring does not have what looks like a solid perch, but they have not

come off by themselves so far in our testing. See Figure 10

8) Push the pins out from the inside of the cartridge. See Figures’

11 & 12

FIGURE 9

|

FIGURE 10

|

| |

|

FIGURE 11

|

FIGURE 12

|

9) Separate the two halves. See Figure 13

NOTE: If You did NOT cut holes in the top of the cartridge,

skip to step 12

10) Remove the drum. Lift the drum out by the drive gear. Pull the drum to

the left, so that it comes off the drum axle pin. See Figures’ 14 &

15

11) Remove the PCR and clean with your standard PCR cleaner. We have been

using Nu-Finish for years with out any problems. See Figure 16

12) Remove the drum cover. Release the spring, and gently pry up the two

sides. Be very careful when removing as the plastic is very delicate! See

Figures’ 17 & 18

FIGURE 13

|

FIGURE 14

|

| |

|

FIGURE 15

|

FIGURE 16

|

| |

|

FIGURE 17

|

FIGURE 18

|

13) Remove the Wiper Blade, this blade is unique to the 1012 series. By the

time you are reading this, new blades should be available. See Figure 19

14) Clean out all the waste toner.

15) Coat the wiper blade with your preferred lubricant, and re-install. See

Figure 20

16) Re-install the cleaned PCR. Note that a new OEM PCR has a small amount

of conductive grease on the black (contact) side. See Figures 21 & 22

FIGURE 19

|

FIGURE 20

|

FIGURE 21

|

FIGURE 22

|

17) Re-Install the OPC Drum. Slide the hub end onto the drum axle and drop

in place. This axle pin is very hard to remove, so this is actually the best

way. See Figures 23 & 24

18) Install the drum cover. This at first glance can be confusing. Slide

the cover on from the handle side of the cartridge. Snap the shaft into place,

and install the spring. See Figures’ 25, 26, & 27

FIGURE 23

|

FIGURE 24

|

FIGURE 25

|

FIGURE 26

|

FIGURE 27

|

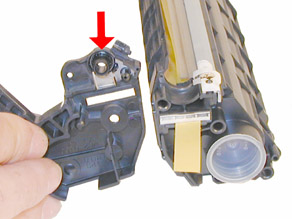

19) On the toner hopper, remove the right

side toner hopper end cap and screw. See Figure 28

20) Remove the three white gears as shown in Figure 29. These gears are loose

and will fall off if not removed.

21) Remove the left side end cap. This is the side that houses the Magnetic

roller contacts and fill plug. See Figure 30.

22) Remove the magnetic roller assembly. Although not necessary, I find it

easier to keep the magnetic roller and end caps all together. Clean out any

remaining toner from the hopper. Make sure that the magnetic roller seals

in the hopper are clean. (These are the same type as used in all the newer

HP cartridges). See Figure 31

FIGURE 28

|

FIGURE 29

|

FIGURE 30

|

FIGURE 31

|

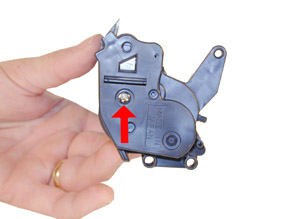

23) If you are going to replace the magnetic roller sleeve, press in

from the metal hub side with a small screwdriver to drive the plastic

hub out. This hub is a different style than previous Canon/HP designs.

The contact hub has a spring, but the end of the magnet does not protrude

from the assembly. It is still keyed however, and when re-installed,

must be set so that the keyed end is in its slot. The black and white

end caps on the roller are unique for each side. The black will fit

both sides but is designed for the contact side, the white will only

fit the non-contact side. See Figures 32, 33, & 34.

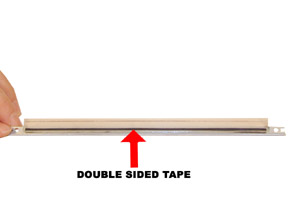

24) Remove the DR. Blade. There is double sided tape under the blade that

keeps it in place, and seal off any leaks. If you are re-using the blade,

a quick swipe with a lint free cloth dampened with alcohol will re-activate

the glue. If not, replace the tape with new double sided tape. If this is

not done, that cartridge will leak. See Figures’ 35 & 36.

FIGURE 32

|

FIGURE 33

|

FIGURE 34

|

FIGURE 35

|

FIGURE 36

|

25) Fill through the Mag roller opening with 150g of 1012 toner. You can

fill through the fill hole but unless a seal is installed, you must hold the

magnetic roller assy. in place, a very tricky thing to do. See Figure 37

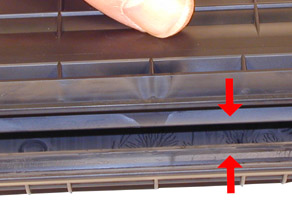

26) If you are going to seal the cartridge, it should be placed on top of

the rail areas shown in Figure 38. The seal tab fits through the right side

of the cartridge (fill plug side). Figure 39 shows both the seal exit slot

and the fill plug. Figure 40 is a close up of the seal exit slot. Figure 41

shows the seal and exit port seal installed. Note that it has a rubber gasket

that seals off the opening. This port seal must be removed before inserting

a seal. Make sure it is put back or the cartridge will leak after the seal

has been removed!

FIGURE 37

|

FIGURE 38

|

FIGURE 39

|

FIGURE 40

|

FIGURE 41

|

27) Re-install the doctor Blade. Remember to clean/replace the double sided

tape seal! See Figure 42

28) Install the left side end cap on the toner hopper. Clean and replace

the conductive grease on the magnetic roller contact plate. See Figures’

43 & 44

29) Re-assemble the toner hopper section. Place the Mag. Roller Assy. in

the hopper, and install onto the contact plate side first. Align the keyed

magnet into the keyed slot. You can see the slot from the outside of the hopper.

See Figure 45

30) Install the right side gears, end cap and screw. See Figures 46 &

47

31) Place the two halves together, and insert the two pins. You will have

to open the drum cover slightly to do this as the arms cover the pin holes.

Make sure that the pins are slightly pushed in so that they do not interfere

with the drum cover arms. See Figures 48, & 49.

32) Install the Right side outer end cap, and two screws. See Figure 50

33) Install the small tension spring across the two halves as shown. The

easiest way is to hook the long side on first, and pull it over with the spring

hook.

See Figure 51

FIGURE

50

|

FIGURE

51

|

Back grounding: (Gray Streaks)

This is usually caused by a dirty/worn out PCR, or a worn out wiper

blade.

Light Print: Can be caused by a dirty/worn Magnetic

Roller or worn doctor blade.

Solid Black Pages: Bad drum ground contact. Probably

from the drum axle shaft to the contact gear inside the drum.

Perfectly straight thin black lines down the page:

Scratched drum.

Black dots that repeat every 3": Bad drum or

something is stuck to the drum surface.

Dark black Horizontal lines: Are usually caused by

either a bad PCR connection, a pin hole in the PCR, or a pin hole in

the drum. These lines normally run about 1/8” thick and can show

as few as 4 times/page and as many as 12 times/page.

“Tire Tracks” on the right edge of the page

are caused by a worn out drum. (Tire Tracks are what we call a vertical

shaded area with lines in it that look like tire tread marks in the

sand. This normally happens to OEM drums.

Half the page prints, the other half is blank: The

cartridge pin on the blank side is most likely not installed correctly.

Remove the pin and re-install making sure that the pin is inserted into

both halves. This can also happen to some degree if the long tension

spring that fits across both halves is missing.

Two pages are available from the front

panel of the printer, the Demo Page, and the Configuration Page.

To run the Demo Page, make sure that the ready light is on, and briefly press

the GO button. The Demo Page will print out.

To run the Configuration Page, make sure that the ready light is on and press

the GO button for 5 seconds. When the GO light turns on, release the button.

Two pages with complete printer info including the page count as well as a

supplies status page will print out.

The cleaning page for these machines can

only be run from the HP-Toolbox. HP recommends that for best results, a transparency

be used. If a transparency is not available, user copier grade paper with

a smooth surface.

To get to the HP-Toolbox, Go to the Windows “Start” Menu, “Programs”,

and “HP LaserJet 1010”. Choose “HP-Toolbox”. The Toolbox

opens in a web browser format.

To run this page, make sure the printer is on and the Ready Light is on.

Access the HP-Toolbox, and click on the “Troubleshooting” tab.

From there, click on the “Print Quality Tools” tab, and finally

the “Cleaning Page”. The cleaning cycle takes up to 2 full minutes.

The page will start and stop. Do not turn the printer off until the cleaning

page has finished printing.

The cleaning process takes about 2 minutes. The cleaning page will stop periodically

during the cleaning process. Do not turn the printer off until the process

has finished.

As with the 1150, 1200 and 1300, these

machines do not have a display panel. All the error codes consist of different

pattern of the three lights. We will update this as soon as the Service Manual

is released.

Top light blinking: Cartridge door open, no print cartridge installed, or

there is a paper jam.

All three lights on: Fatal error; turn the printer off, and unplug it for

30 minutes. If the error still exists, the printer has a major problem. There

is no information yet on what these problems may be. (The service manual has

not been released yet).

All three lights blinking: A printer initialization is in progress.

All three lights cycle in sequence: The printer is initializing, the cleaning

page is being run, or a job cancel command has been sent.

© 2003 Summit Laser Products, Inc. Any attempt to reproduce any part of

these instructions without the written consent of Summit Laser Products, Inc is

prohibited. All registered trademarks are the property of their respective

owners.

Contact Summit Laser Products

Toll Free Orders:

800-221-3516

Toll Free Fax: 888-791-9188

International Orders:

+1-631-218-8376

International Fax: +1-631-218-3285

Domestic Sales E-mail: sales@summitlaser.com

International Sales E-mail: export@summitlaser.com

Technical Support:

+1-631-218-8376

Technical Support E-Mail: tech@summitlaser.com

Mail: Summit

Laser Products

95 Orville Drive, Bohemia, New York 11716 - USA

Please report any broken links to:

webmaster@summitlaser.com

Authorized Summit Laser Distributors

All products on this web site, unless stated otherwise, are independently produced and distributed by Summit Laser, and not by the individual manufacturers of the copiers and printers referenced herein. Use of trade styles and trademarks of the individual manufacturers of the copiers and printers referenced herein are for descriptive purposes only and are not intended to imply any form of endorsement by the individual manufacturers of the refill or supply products offered herein. As such, all items in this catalog are deemed to be construed as “for use in,” “for use with or compatible with,” whether or not stated for each individual item as opposed to the group of items.

|