|

|

Remanufacturing the Brother HL

5150 Toner Cartridges TN-540/TN-570 (TN-3030/TN-3060 Europe) |

Remanufacturing the Brother HL

5150 Toner Cartridges

TN-540/TN-570

Released in May 2004, the Brother HL-5150 printer engine is based on a new 21ppm, 1200 DPI laser engine. This is the latest engine based on the Brother HL-1240 (TN-460) engine. While it is similar, there are differences. The main difference is the toner. TN-460 toner will not work well in these cartridges. The first section of this article covers the theory behind these cartridges. If you are already familiar with the pitfalls of the HL-1240 cartridges, there is nothing new in the theory here. If you are not however, it would be best to read through this section. It may save you a few very frustrating hours. As you can see below, Brother has released quite a few machines all at once based on this engine. These cartridges are going to be very popular. The machines based on the HL-5150 engine are as follows: DCP-8040 As with the TN-460 cartridges, the reason the high yield cartridge gets double the yield by using approximately 50% more toner has to do with this engines unique toner sensing system. These cartridges routinely leave as much as 80 grams of toner in the supply chamber, all the while showing toner out and refusing to print! Shaking the cartridge at this point will only get you another 25-30 pages before the printer shuts down again. The remaining toner (80g or so!), MUST be completely removed from the supply chamber before adding new toner. Failure to do this will cause back grounding. In addition to contaminating the toner cartridge, this will also contaminate the cleaning section of the drum cartridge, which in turn will contaminate the toner cartridge again. The cleaning section of the drum cartridge consists of a "cleaning brush" and a recovery blade. The cleaning brush has two opposite charges placed on it during the print cycle. The first attracts any remaining toner off the drum. The second repels the toner off the brush back onto the drum where it then transfers back into the toner cartridge. This is all done in a timing sequence that does not interfere with the printing process. If the cleaning brush becomes contaminated with bad toner that will not charge, the brush will not be able to clean itself, and back grounding will occur. It seems to be the nature of contaminated toner that it will accept most of the charge to be cleaned off the drum, but it will not accept the charge that would allow the brush to clean itself off at all. A properly working cleaning brush will at any given time have only a small amount of toner on it. Once contaminated, toner will accumulate, which will only cause the problems to get worse. Since the developer roller actually contacts the drum, some toner is transferred back into the supply of the toner cartridge. Once you print with a bad toner cartridge, the drum unit will become contaminated. Even when you change out the toner with a good properly recycled or new OEM cartridge, the drum unit will transfer some of the bad toner back into the good toner cartridge, which will again cause back grounding. Both cartridges will be contaminated again. The remaining 80g or so of "toner" in the toner cartridge is just below the bare minimum that can maintain the proper charge level. When the change toner light comes on, the toner will not charge up to the proper level and will cause the back grounding. As the toner cartridge reaches the end of it's useful life, the printer senses the low charge level in the toner supply and will try to keep the charge level up. This constant charging keeps an almost "empty" cartridge from back grounding. Once the printer cannot get the remaining toner up to the minimum charge, the change toner light comes on. The cartridge at this point will still be printing properly. If you were to take that same cartridge out of the machine for a few days, and then put it back in the printer with out doing anything to it, the cartridge will shade. This will happen because the charge level that the printer was trying so hard to keep up has dissipated out and the materials left can no longer accept a proper charge. 1) Make sure that your cartridge technicians thoroughly clean out the supply chamber of the toner cartridge. 2) In the event that they forget, and you have a shading cartridge. The toner must be completely cleaned out again. (Do not use the toner over!!), and NEW fresh toner MUST be installed. 3) The drum unit has to be taken apart and cleaned out with emphasis on the cleaning brush area. This is a very simple process but very necessary once contaminated. How to run test pages, Printer trouble shooting as well as common cartridge problems will be covered at the end of this article.

Figure’s 1-9 show the differences between the TN-460, TN-560, and the TN-570 toner cartridges.

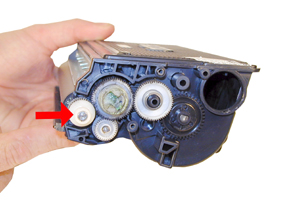

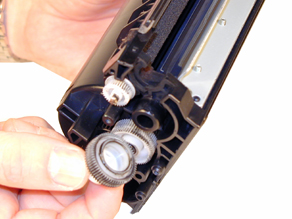

1) Vacuum the exterior of the cartridge. 2) Remove the fill plug from the toner cartridge. Dump the remaining toner and vacuum/blow out the cartridge. Make sure that the gear area is clean. Leaving any toner in the teeth of the gears may cause a tooth to be damaged and cause a clicking noise. We have found it best to use compressed air to clean them out, but to also keep one hand over the gears to protect them. See Figure 10 3) On the NON GEAR side of the static roller, pry off the black spring loaded plastic axle. See Figure 11 4) Locate the three tabs on the static roller end plate and pry off. See Figure 12 5) On the GEAR SIDE, remove the two screws and cover plate. See Figure 13

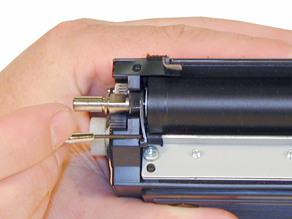

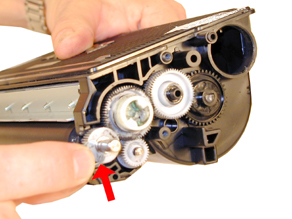

6) Pry off the white plastic axle. See Figure 14 7) Remove the E-Ring, and small gear. See Figure 15 8) On the doctor blade side of the static roller, there is another small plate that is located on the end of the roller and inside the plastic wall of the cartridge. From the outside of the wall locate a small round hole. Press in the round tab located inside the hole. While pressing in turn the plate up so that the plate and roller are free. See Figure's 16 & 17

9) Remove the static roller assembly. See Figure 18 10) Vacuum the doctor blade and foam feed roller clean. We do not recommend that the doctor blade be removed and the static roller felt seals will be disturbed. Once a new blade is available, great care will have to be taken not to tear the seals, causing a leak. The doctor blade can be easily cleaned by blowing the excess toner off, and wiping down with a lint free cloth. Be very careful not to leave any lint behind! See Figure 19 11) Inspect the magnetic roller felts. If they are compressed, (shiny) rough them up with a small screwdriver. See Figure 20 12) Clean the gears, making sure that the fine toothed gears have no toner on them. This is a good time to also check the gear shafts to make sure there is enough grease. If the shafts appear dry, or the grease is contaminated with toner, clean the shaft and inside of the gear. Replace the grease with white lithium grease. See Figure 21

13) Clean the static roller with a lint free cloth. Do not use any chemicals to clean the roller. A dry clean cloth will work fine. See Figure 22 14) Re-install the static roller, inside end plate first. Turn the inside plate so that it locks in place. See Figure 23 15) Install the small outside end plate, and both the spring-loaded white axle and the non-spring axle. See Figure's 24 & 25

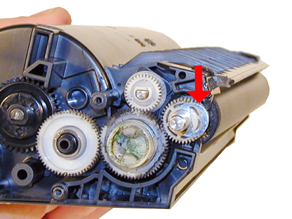

15) Install the static roller gear, c-ring, and white axle. Make sure all the other gears are meshing properly. See Figure’s 26, 27, & 28 16) Install the gear cover plate, and two screws. See Figure 29

17) Fill the cartridge with Brother 5150 Black Toner (140g for TN540,(TN3030), 200g for TN570,(TN3060). See Figure 30 18) Replace the fill plug. See Figure 31 19) Wipe the cartridge down to remove any remaining toner dust. There are no reset fuses or procedures for this cartridge.

To print a test page from these machines, first turn the machine off. Press and hold the “GO” Button, and turn the printer back on. All the LED’s will light up, and go off. When the TONER LED comes on, release the “GO” button. Press the “GO” Button again; the printer will print out the test page. This can also be accomplished through the printer driver.

These machines have 4 LED’s to indicate the status or various problems. We have listed some of the more common ones here: Toner light blinking: Toner Low When the GO and JOB CANCEL buttons are pressed together, a secondary set of errors will show. TONER Yellow and STATUS Red

lights on: Fuser error

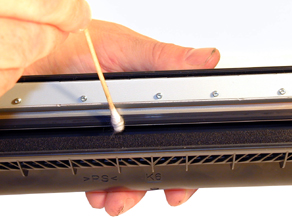

As some problems can be caused by both the toner cartridge as well as the drum cartridge, we have listed both here. Back-grounding: Toner cartridge and Drum cartridge; By far the most common problem with these cartridges, there are three major common causes. 1) The first is contaminated toner. If the old toner in the toner cartridge was not fully cleaned out, a shaded background will result usually over the entire page. This can also be caused by a contaminated cleaning brush in the drum cartridge, which is directly related to a bad toner cartridge. (See cartridge theory at the beginning of this article). 2) If the developer roller in the toner cartridge is worn, it will tend to pull too much toner, and back-grounding will result. This normally happens only on cartridges that have been recycled a few times. A normal roller will have a somewhat mottled look, and the texture should be smooth. If the roller has lines, small cracks, or just doesn’t look right, don’t use it. A dirty developer roller can also cause this. If the roller has a white or bluish coating, it must be cleaned. Be sure to use only a dedicated Brother developer roller cleaner. Any other type of cleaner will probably react with the toner and cause another set of problems. 3) Another back-grounding issue can result from the toner being used. Not all aftermarket toners will work together. This is because there is always a small amount of toner left on the drum cartridge cleaning brush. Most aftermarket toners will work over the OEM, but not all will work over another aftermarket toner. If your cartridges work in house but background out in the field, it can be that the drum unit has failed, or that another aftermarket toner was used previous to yours. Check with your vendor to make sure that your toner will work on top of another (all) aftermarket brand(s). Clicking: Toner Cartridge; On the left side of the cartridge there is a series of gears with very fine teeth. If any toner gets on these teeth during the cleaning process, and is not cleaned off, the toner can cause a tooth to break, and clicking will result. We have found it easy to keep one hand over the gear train when blowing the cartridge out and when filling it, that way the gears stay clean. If they do get toner on them, clean the gears and the shafts with alcohol, and lubricate with fine grease. Both the shafts and teeth need to be lubricated. Clicking gears can also result from toner not specifically designed for the TN-540/570 being used. If the toner particles are not uniform, the toner will not flow easily, and the mixing auger inside the toner cartridge can bind, causing a tooth to break. Dark Black Vertical Streaks: Drum cartridge; This is normally caused by either a dirty primary corona wire, or the blue corona wire cleaner is not in its "home" position on the left side of the cartridge. Gray Vertical Streaks: This is normally caused by a groove in the developer roller. If the roller has a groove worn in it, it must be either replaced, or re-surfaced by a company that specializes in this. Light Print: Drum cartridge; Can be caused by a dirty or worn Transfer Roller. These rollers are located inside the cartridge. In our tests, they should last at least 2-3 cycles. Black or white horizontal Lines: Toner cartridge and Drum cartridge; Black lines normally appear when there is a build up of toner, White when there is a dead spot, or contamination of the roller. If the lines repeat every 94 mm (approx. 3 3/4"), the drum is bad, or dirty. If they appear every 39mm (approx. 1 9/16"), the developer roller in the toner cartridge is bad or dirty. Solid Black Pages: Drum cartridge; Bad drum ground contact, probably from the drum axle shaft to the contact gear inside the drum. Perfectly straight thin black lines down the page: Drum cartridge; Scratched drum. Black dots that repeat every 94mm (3 3/4"): Drum cartridge; Bad drum, or something is stuck to the drum surface.

© 2003-2004 Summit Laser Products, Inc. Any attempt to reproduce any part of these instructions without the written consent of Summit Laser Products, Inc is prohibited. All registered trademarks are the property of their respective owners.

|