Remanufacturing

the

Brother HL-5150

“DR-510” OPC Cartridge (DR-3000 outside North America.)

0348

First introduced in April 2004, the HL-5150 laser

printers are the next generation of Brother's newer higher quality

engines. The 5150 engine replaces the 1650 (TN-560) engine in the

Brother line. As with all previous Brother engines, it has its

quirks but is better than the previous engine. Last month we went

over the TN-540/570 toner cartridges, this month we finish up with

the DR-510 drum cartridge.

The HL-5150D printer is a 21ppm, 1200 dpi machine

that comes standard with a duplexer built in. With a list price of

$241 including the duplexer, these machines are going to be very

popular. In the HL series, only the HL-5140 does not come with a

duplexer at this time. In a recent PC magazine test, the HL-5140

came up as the Editors Choice for a personal printer, beating

another recently tested 35ppm printer in print speed! Their only

problem with this machine, and I have to agree is that the graphics

are not what you would expect from a modern monochrome printer.

In June 2004, I found pricing on the DR-510 ranging

anywhere from $98.70 to $149.88 on the internet.

Currently there are quite a few machines based on the

HL-5150 engine:

DCP-8040

DCP-8045D

HL-5130

HL-5140

HL-5150D

HL-5150DLT

HL-5170DN

HL-5170DNLT

MFC-8820

MFC-8440

MFC-8840D

MFC-8840DN

When it comes to the DCP and MFC machines be sure to

note the correct model number of your customer’s machine. There are

several machines with very similar model numbers that use different

cartridges! For example, the MFC-8420 uses the HL-1650 engine

(DR-500), but the 8440 uses the new HL-5150(DR-510) engine!

The OEM stated yield is ESTIMATED at 20,000 pages.

There are disclaimers in the manual that basically say you will not

get anywhere near that yield. The following is taken directly from

the HL-5150 user manual:

"Under ideal conditions, the average drum life is

estimated at 20,000 pages. The actual number of pages that your drum

will print may be significantly less than this estimate. Because we

have no control over the many factors that determine the actual drum

life, we cannot guarantee a minimum number of pages that will be

printed by your drum."

Also keep in mind that this is a duplex machine. If

the user uses this feature, they may think the yield appears less

than it is.

Because of the nature of these machines we have

included the cartridge theory here again. It is basically the same

as the TN-460/560 cartridges. If you familiar with those cartridges

and how they work, you can skip to step 1. If not however, we highly

recommend that anyone doing these cartridges read the next section.

It can save you hours of needless troubleshooting.

The cleaning

section of the drum cartridge consists of a "cleaning brush" and a

recovery blade. The cleaning brush has two opposite charges placed

on it during the print cycle. The first attracts any remaining toner

off the drum. The second repels the toner off the brush back onto

the drum where it then transfers back into the toner cartridge. This

is all done in a timing sequence that does not interfere with the

printing process. If the cleaning brush becomes contaminated with

bad toner that will not charge, the brush will not be able to clean

itself, and back grounding will occur. It seems to be the nature of

contaminated toner that it will accept most of the charge to be

cleaned off the drum, but it will not accept the charge that would

allow the brush to clean itself off at all. A properly working

cleaning brush will at any given time have only a small amount of

toner on it. Once contaminated, toner will accumulate, which will

only cause the problems to get worse.

Since the

developer roller actually contacts the drum, some toner is

transferred back into the supply of the toner cartridge. Once you

print with a bad toner cartridge, the drum unit will become

contaminated. Even when you change out the toner with a good

properly recycled or new OEM cartridge, the drum unit will transfer

some of the bad toner back into the good toner cartridge, which will

again cause back grounding. Both cartridges will be contaminated

again.

The remaining

80g or so of "toner" in the toner cartridge is just below the bare

minimum that can maintain the proper charge level. When the change

toner light comes on, the toner will not charge up to the proper

level and will cause the back grounding. As the toner cartridge

reaches the end of its useful life, the printer senses the low

charge level in the toner supply and will try to keep the charge

level up. This constant charging keeps an almost "empty" cartridge

from back grounding. Once the printer cannot get the remaining toner

up to the minimum charge, the change toner light comes on. The

cartridge at this point will still be printing properly. If you were

to take that same cartridge out of the machine for a few days, and

then put it back in the printer with out doing anything to it, the

cartridge will shade. This will happen because the charge level that

the printer was trying so hard to keep up has dissipated out and the

materials left can no longer accept a proper charge.

What does

this all mean?

1) Make sure

that your cartridge technicians thoroughly clean out the supply

chamber of the toner cartridge.

2) In the event

that they forget, and you have a shading cartridge. The toner must

be completely cleaned out again. (Do not use the toner over!!), and

NEW fresh toner MUST be installed.

3) The drum unit

has to be taken apart and cleaned out with emphasis on the cleaning

brush area. This is a very simple process but very necessary once

contaminated.

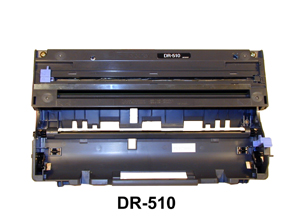

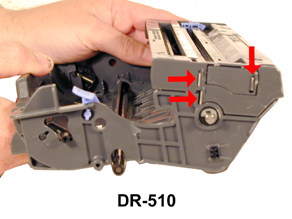

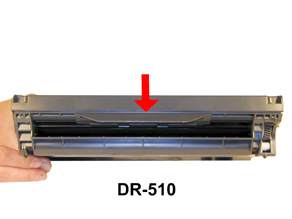

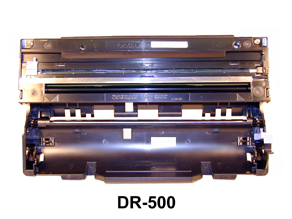

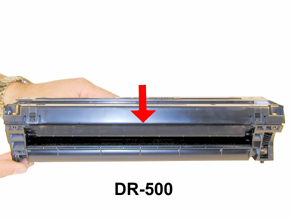

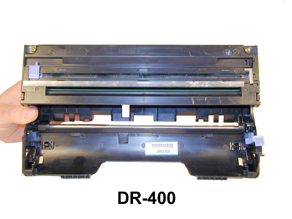

Figures 1

through 12 show the physical differences between the DR-400, DR-500

and DR-510. Note the difference in the bottom slots for the toner

cartridge, the different contacts on the side of the cartridge, and

the plastic extension at the rear of the cartridges.

These

differences make them NOT interchangeable.

|

|

Figure 1 |

Figure 2 |

|

|

|

Figure 3 |

Figure 4 |

|

|

|

Figure 5 |

Figure 6 |

|

|

|

Figure 7 |

Figure 8 |

|

|

Figure 9 |

Figure 10 |

|

|

Figure 11 |

Figure 12 |

1) Remove the

top two screws See Figure #13

2) Lift the top

cover up and remove from the cartridge. See Figure #14

3)Remove

the E-ring from the Non Gear side of the drum axle shaft. See Figure

#15

4) Remove the

opposite E-ring. See Figure #16

|

|

Figure 13 |

Figure 14 |

|

|

Figure 15 |

Figure 16 |

5) Remove the

drum axle from the Non Gear side of the drum. If you try to pull it

out from the gear side, the shaft will jam up on the drum ground

contact and damage the contact. See Figure #17

6) Be careful

not to loose the round drum spacer. See Figure #18

7) Carefully

remove the drum. Note that the gear side actually has two gears. One

attached, one not. The opposite side has a separate hub and spring.

Do not loose these parts! See Figure #s 19, and 20.

|

|

Figure 17 |

Figure 18 |

|

|

Figure 19 |

Figure 20 |

8) Carefully

lift out the transfer Roller. Be very careful not to touch the

roller with your skin. As with any transfer Roller, the oils

naturally present in your skin will be absorbed by the roller and

interfere with the transfer process, causing light print. See Figure

# 21

9) IMPORTANT:

Note the small piece of black plastic spacer on the right side of

the roller, (side opposite the gear). This spacer keeps the transfer

roller touching the electrical contacts on the left side of the

cartridge. Be very careful not to loose this spacer! The cartridge

will either print very light or 1/2 pages if it is missing. It is

best to remove this spacer while cleaning the cartridge. See

Figure's 22 and 23

10) With

compressed air, blow off the Transfer roller. Unless you have a

statically grounded vacuum, do not vacuum this roller.

11) Vacuum or

blow off the cleaning felt assembly. Make sure you remove any

remaining toner from the felts, or the brush itself. Be very careful

not to damage the recovery blade located next to the cleaning brush.

Vacuum any remaining toner from the rest of the cartridge. The

entire assembly can be removed by removing the two screws, but this

is not normally necessary. See Figures 24 & 25

|

|

Figure 21 |

Figure 22 |

|

|

Figure 23 |

Figure 24 |

12) Reinstall

the small black transfer roller spacer. See Figure 26

13) Install the

transfer roller. Make sure the U-shaped holders fit into their

respective slots. See Figure 27

14) Check the

outside of the cartridge to make sure that the small black spacer is

correctly positioned. See Figure 28

|

|

Figure 25 |

Figure 26 |

|

|

Figure 27 |

Figure 28 |

15) Install the

drum and associated gear, hub, and spring. See Figure 29

16) Install the

drum axle from the drum gear side of the cartridge. See Figure 30

17) Install the

black drum axle spacer. See Figure 31

18) Install the

two E-rings on each side of the drum axle. See Figure 32

|

|

Figure 29 |

Figure 30 |

|

|

|

Figure 31 |

Figure 32 |

19) Clean the

primary corona wire and grid with a cotton swab and alcohol. See

Figure 33

20) Install the

top cover, hook the back edge over the tab, and press down. See

Figure 34

21) Install the

top two screws. See Figure 34

|

|

Figure 33 |

Figure 34 |

|

|

Figure 35

|

If the machine

is saying to change the drum unit, do the following. If the drum

unit was cleaned because of contamination, the reset is not

necessary.

After replacing

the drum unit, keep the front cover open (make sure the power is

on). Press and hold the "GO" button until all four LEDS are lit.

Once the four LEDs are lit, close the front cover. Make sure the

Drum LED is off.

The counter is

reset!

Back

grounding:

(Gray Streaks) This is usually caused by contaminated toner. See the

explanation at the beginning of this article for more information.

Dark Black

Vertical Streaks:

This is normally caused by either a dirty primary corona wire, or

the blue corona wire cleaner is not in its "home" position on the

left side of the cartridge.

Light Print:

Can be caused by a dirty or worn Transfer Charge Roller. These

rollers are located inside the cartridge. So far in our tests, they

should last at least 2-3 cycles. See next section also.

Light or 1/2

page prints:

This is caused by a missing transfer roller spacer. The spacer is a

small piece of black plastic that sits next to the right end of the

transfer roller. This piece keeps the transfer roller touching the

electrical contact on the opposite side of the roller. If missing,

the roller will move and can cause light or 1/2 page prints.

Black or white

horizontal Lines:

Black lines normally appear when there is a build up of toner, White

when there is a dead spot, or contamination of the roller. I the

lines repeat every 94 mm (approx. 3 3/4"); the drum is bad, or

dirty. If they appear every 39mm (approx. 1 9/16"), the developer

roller in the toner cartridge is bad or dirty.

Solid Black

Pages:

Bad drum ground contact. Probably from the drum axle shaft to the

contact gear inside the drum.

Perfectly

straight thin black lines down the page:

Scratched drum.

Black dots that

repeat every 94mm (3 3/4"):

Chipped drum or something is stuck to the drum surface.

© 2003-2004 Summit Laser Products, Inc.

Any attempt to reproduce any part of these instructions without the written

consent of Summit Laser Products, Inc is prohibited. All registered trademarks

are the property of their respective owners.

|