|

First introduced in April 2004, the HL-6050 laser printers are the

next generation of Brother's newer higher quality engines. Last

month we went over the TN-670 toner cartridges, this month we finish

up with the DR-600 drum cartridge.

The HL-5150D

printer is a 24ppm, 1200 dpi machine that comes standard with a duplexer built

in. With a list price of $241 including the duplexer, these machines are

going to be very popular.

In July 2004,

I found pricing on the DR-600 ranging anywhere from $93.88 to $149.99 on the

internet.

Currently

there are two machines based on the HL-6050 engine: The HL-6050, HL-6050D,

HL-6050DN, and the HL-6050DW

The OEM

stated yield is ESTIMATED at 30,000 pages. There are disclaimers in the

manual that basically say you will not get anywhere near that yield. The

following is taken directly from the HL-6050 user manual:

"At

5% print coverage (A4 or letter size). The actual number of printed pages will

vary depending on the average type of print job and paper.

There are

many factors that determine the actual drum life, such as the temperature,

humidity, type of paper, type of toner used, number of pages per print job and

so on. Under ideal conditions, the average drum life is estimated at up to

30,000 pages. The actual number of pages that your drum will print may be

significantly less than this estimate. Because we have no control over the many

factors that determine the actual drum life, we cannot guarantee a minimum

number of pages that will be printed by your drum.”

We are not including the theory on these cartridge again as

it is basically the same as the TN-460/560 cartridges. The difference here is

that instead of a cleaning felt, these cartridges use a cleaning roller

assembly. This assembly still returns the toner back to the toner cartridge as

the felt did, but this roller also has a chamber that collects small amounts of

toner that did not charge and paper dust. All this must be removed. The best way

is with compressed air.

In our tests so far, the cleaning roller system seems to

work better than the felt, but testing is still on going. Time will tell…

Supplies Needed

Tools Required

Disassembly

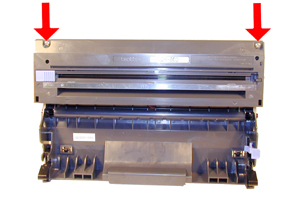

1) Remove the top two screws See Figure 1

2) Lift the

top cover up towards the empty toner cartridge cavity and remove from the

cartridge. See Figure 2

3) Remove the

E-ring from the Non Gear side of the drum axle shaft. See Figure 3

4) Remove the

opposite E-ring. See Figure 4

|

|

Figure 1 |

Figure 2 |

|

|

Figure 3 |

Figure 4 |

5) Remove the drum axle from the Non Gear side of the drum. If you

try to pull it out from the gear side, the shaft will jam up on the

drum ground contact and damage the contact. See Figure 5

6) Be careful

not to loose the round drum spacer. See Figure 6

7) Carefully

remove the drum. Note that the gear side actually has two gears. One attached,

one not. The opposite side has a separate hub and spring. Do not loose these

parts! See Figure 7 and 8.

|

|

Figure 5 |

Figure 6 |

|

|

Figure 7 |

Figure 8 |

8) Carefully lift out the cleaning roller assembly. Be very careful

not to touch the roller with your skin. As with any cleaning Roller,

the oils naturally present in your skin will be absorbed by the

roller and interfere with the cleaning process. See Figure 9

9) Lift out

the transfer roller assembly. Be very careful not to touch the roller with your

skin. The oils naturally present in your skin will be absorbed by the roller and

interfere with the transfer process, causing light print. See Figure 10

10) IMPORTANT: Note the small piece of black plastic spacer on the right side of

the roller, (side opposite the gear). This spacer keeps the transfer roller

touching the electrical contacts on the left side of the cartridge. Be very

careful not to loose this spacer! The cartridge will either print very light or

1/2 pages if it is missing. It is best to remove this spacer while cleaning the

cartridge. See Figure's 11 and 12

|

|

Figure 9 |

Figure 10 |

|

|

Figure 11 |

Figure 12 |

11) With compressed air, blow off the Transfer roller. Unless you

have a statically grounded vacuum, do not vacuum this roller.

12) Reinstall

the small black transfer roller spacer. See Figure 13

13) Install

the transfer roller. Make sure the U-shaped holders fit into their respective

slots. See Figure 14

14) Check the

outside of the cartridge to make sure that the small black spacer is correctly

positioned. See Figure 15

15) Install

the drum and associated gear, hub, and spring. See Figure 16

|

|

Figure 13 |

Figure 14 |

|

|

Figure 15 |

Figure 16 |

16) Install the drum axle from the drum gear side of the cartridge.

See Figure 17

17) Install

the black drum axle spacer. See Figure 18

18) Install

the two E-rings on each side of the drum axle gear side first. See Figure 19

19) Remove

the three screws that hold the cleaning roller assembly together. Pry the cover

off. Vacuum or blow off the cleaning roller. The dust inside is a combination of

toner and paper dust, all of it must be removed. Make sure you don’t loose the

gears! See Figures 20 & 21

|

|

Figure 17 |

Figure 18 |

|

|

Figure 19 |

Figure 20 |

20) Install the 3 screws into

the cleaning assembly. See Figure 22

21) Install

the cleaning roller assembly and two screws. Check to make sure the two contact

springs are not dirty or bent. See Figure 23

22) Clean the

primary corona wire and grid with a cotton swab and alcohol. See Figure 24

|

|

Figure 21 |

Figure 22 |

|

|

|

Figure 23 |

Figure 24 |

23) Install the top cover, hook the back edge over the tab, and

press down. See Figure 25

24) Install

the top two screws. See Figure 26

Reset Procedure

Press the cover release button, and open the front cover.

With the cover still open, Press and hold the GO button until "Drum

Clear" is displayed. Release the GO button.

The counter is reset!

Troubleshooting

Back grounding: (Gray Streaks) This is usually caused by contaminated toner. Clean

all remaining dust from the cleaning roller assembly, blow cleaning

roller clean with compressed air.

Dark Black Vertical Streaks: This is normally caused by either a dirty primary corona wire, or

the blue corona wire cleaner is not in its "home" position on the

left side of the cartridge.

Light Print: Can be caused by a dirty or worn Transfer Charge Roller. These

rollers are located inside the cartridge. So far in our tests, they

should last at least 2-3 cycles. See next section also.

Light or 1/2 page prints: This is caused by a missing transfer roller spacer. The spacer is a

small piece of black plastic that sits next to the right end of the

transfer roller. This piece keeps the transfer roller touching the

electrical contact on the opposite side of the roller. If missing,

the roller will move and can cause light or 1/2 page prints.

Black or white horizontal Lines: Black lines normally appear when there is a build up of toner, White

when there is a dead spot, or contamination of the roller. I the

lines repeat every 94 mm (approx. 3 3/4"); the drum is bad, or

dirty. If they appear every 39mm (approx. 1 9/16"), the developer

roller in the toner cartridge is bad or dirty.

Solid Black Pages: Bad drum ground contact. Probably from the drum axle shaft to the

contact gear inside the drum.

Perfectly straight thin black lines down the page: Scratched drum.

Black dots that repeat every 94mm (3 3/4"): Chipped drum or something is stuck to the drum surface.

|