Remanufacturing

the Samsung ML-2250 Toner Cartridge

0353

First released in July

2004, the Samsung ML-2250 printers are based on a 22ppm, 1200dpi

engine.

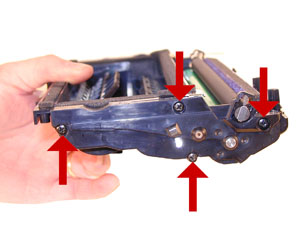

These cartridges are very similar to the ML-1750, but there are

differences. The main difference is that some of the ML-1750 cartridges

have a fuse to reset the printer. The ML-2250 cartridges use a series

of different chips. The actual ML-2250 doesn’t use anything

but all the rest so far use a special chip. A chart below will list

all the different variations. Figures 1 & 2 show different views

of the cartridge, basically the 2250 series are a bit flatter that

other Samsungs.

These cartridges do not have a drum cover, and come new with a

piece of heavy paper taped around the cartridge. All new cartridges

opened so far have shown some toner leakage on the drum that would

have shown on any prints.

The standard cartridge (Samsung part# ML-2250D5/XAA) comes new

with 120g toner, and is rated for 5,000 pages at 5% coverage. Other

brands based on the 2250 have a low yield cartridge rated for 3,000

pages. They are also listed in the chart below. In some cases, the

cartridges do not have the branded part number on them. For those

cases, we have listed the part numbers that are on the cartridge

label. (Samsung manufacturing code)

1) Place the cartridge with the handle facing up. Remove the 5

top cover screws. See Figure 3

2) On the front edge of the cartridge, there are two tabs. Press

these two tabs in, and lift the front edge of the cover up. See

Figure 4

3) Next to the handle of the cartridge to the right and left, there

are 2 more plastic tabs. GENTLY press them in, and remove the cover.

See Figure 5

CAUTION: The upper half of the toner hopper is being removed. If

there is a lot of toner left in the hopper, it can dump out all

over! Vacuum the hopper clean.

4) With the toner hopper away from you, remove the four screws

on the left side end cap. Remove the end cap. See Figure 6

|

|

Figure 3 |

Figure 4 |

|

|

|

Figure 5 |

Figure 6 |

5) Remove the four screws on the right side end cap. Remove the

end cap. See Figure’s 7 & 8

6) Remove the PCR. See Figure 9

7) Also on the right side there is a series of gears under the

end cap. Make a note of the location of each gear, and remove them.

See Figure 10

8) Clean the PCR with your normal PCR cleaner.

WARNING: Do not clean the OEM PCR with alcohol, as this will remove

the conductive coating from the roller. If the PCR is an aftermarket,

follow the cleaning methods recommended by the manufacturer. If

the PCR is an OEM, we recommend it be cleaned with your standard

PCR cleaner.

|

|

Figure

7 |

Figure

8 |

|

|

Figure

9 |

Figure 10 |

9) There are 2 screws on the PCR cleaner Assy.

Remove them and gently pry the blade up. Be careful not to damage

the alignment pins. This PCR cleaner also has what can be considered

a wiper blade. It is a very flimsy blade attached to the metal bar.

Wipe this blade down with a clean lint free cloth before re-installing.

See Figures 11, 12 & 13

10) It is very important that the PCR cleaner be cleaned. Vacuum

or blow off any residual toner from the foam/felt.

11) With the PCR Cleaner Assembly removed, the drum can easily

be removed by lifting it out. See Figure 14

12) Clean out any remaining toner from the cartridge.

|

|

Figure

11 |

Figure

12 |

|

|

|

Figure

13 |

Figure

14 |

13) Press in on the bottom tab of the Developer

roller plate (Right (Gear) Side) to release it. See Figure 15

14) With a small common screwdriver, press the entire plate towards

the edge of the developer roller cavity, and lift up. The Plate

should come loose. See Figure 16

15) Gently pry out the roller plate from the cartridge. The foam

seal, and possibly a plastic flat washer will come out with it.

Be careful not to damage the foam seal, or loose the flat washer.

See Figure 17

16) Remove the Developer Roller. Be careful not to damage or lose

the flat washers on the roller. See Figure 18

|

|

Figure

15 |

Figure

16 |

|

|

|

Figure

17 |

Figure

18 |

17) It is highly recommended that the Doctor Blade be cleaned.

Failure to do so will cause streaking. The Doctor Blade can be cleaned

with out removing it. Dampen a cotton swab with alcohol, and clean

the blade. Be careful not to press too hard and damage the blade.

If the blade has a heavy buildup of toner on it, clean it with Acetone,

and then alcohol. Removing the blade is difficult because of the

foam seals attached. If the seals are torn, the cartridge will leak.

That is why we do not recommend it. Once replacement Dr. Blades

are available, they will have to come with replacement foam. See

Figure 19

18) Replace the Developer roller, and flat washers. See Figure

20

19) If no grease is left on the gears and gear shafts, or it is

contaminated with toner clean it all off. Replace it with white

lithium grease. Be sure to clean and grease the gear shafts, and

inside the gear. See Figure 21

20) Install the roller plate. Make sure the tab is locked in place

See Figure 22

|

|

Figure

19 |

Figure

20 |

|

|

|

Figure

21 |

Figure

22 |

21) Replace the roller plate and 7 gears. Look carefully at the

picture of the gears. Each gear must fit in this exact way. The

gears labeled in order of installation. See Figure 23

22) Install the new drum in place. See Figure 24

23) Install the PCR cleaner Assy. and two screws. See Figure 25

24) Clean the conductive grease off the left side (Non Gear) end

cap and replace with fresh grease. Replace the end cap and four

screws. See Figure 26

|

|

Figure

23 |

Figure

24 |

|

|

|

Figure

25 |

Figure

26 |

25) Install the PCR. Make sure that the PCR gear is on the correct

side and that the shaft is in the PCR holder. See Figure 27

26) Install the right side end cap, and 4 screws. Make sure the

PCR fits correctly in its holder, and all the gears are aligned.

See Figure 28

27) Fill the hopper with the appropriate amount of toner. See Figure

29

This can also be done through the fill plug, but the fill plug

tends to leak and will probably have to be sealed with silicon.

28) If the is a chipped cartridge, replace the chip now. Make sure

the chip you install is the correct one for the machine it is to

be installed in. New reset boxes are now available that can change

the personality of the chip across the full line. This will enable

you to test the cartridge in your test machine, and than change

the chip to work in your customer’s machine if different.

See Figure 30

|

|

Figure

27 |

Figure

28 |

|

|

|

Figure

29 |

Figure

30 |

29) Carefully snap the cover on making sure all the tabs lock in

place. See Figure’s 31 & 32

30) Install the five screws in the top cover. See Figure 33

|

|

Figure

31 |

Figure

32 |

|

|

|

Figure

33 |

|

NOTE: All the following is based on the

ML-2250. Other branded machines may be different.

Printing Test Pages:

Test pages from these machines are very easy to run. Timing is

the only issue here

Demo Page

Press and hold the “CANCEL” button for 2 seconds. A

demo page will print out

Configuration Page:

Press and hold the “CANCEL” button for 6 seconds. The

configuration page will print out

Cleaning Page

Press and hold the “CANCEL” button for 10 seconds.

The cleaning page will print out

Common Cartridge Problems

Even Light Prints: Check to see if the Toner Save feature has been

enabled. The Toner Save light will be on. This is accessed from

the printer driver properties.

A Dirty or Bad Primary Charge Roller (PCR); located Inside the

cartridge, this will show on the test print as vertical gray streaks

down the page, as a gray background throughout the page, as ghosting

where part of a previously printed area is repeated, or as a mark

that repeats every 38mm.

Dirty PCR Connection; This will show as horizontal dark black bars

across the page, or as shading throughout the page.

Scratched Drum; This is shown by a very thin, perfectly straight

line that runs from the top to the bottom of the test page.

Chipped Drum; This will show as a dot or series of dots that repeat

every 76mm.

Light Damaged Drum; This will show up as a shaded area on the test

print that should be white. Again this will repeat every 76mm.

Bad Wiper Blade; This will show as either a gray line approximately

1/8" thick, or as shading across the entire page. In either

case there will be a film of toner on the drum surface.

Bad Developer Roller; This will show up as light print or as a

mark that repeats every 44mm

Machine Error Codes:

These machines do not have a display panel. They use a series of

LED’s to indicate a problem. There are two lights on the control

panel, the ONLINE/ERROR, and the TONER SAVE lights. The Online light

is a two color LED, Red and Green.

The user manual for these machines only has very basic information

listed as follows:

If both lights are blinking, the machine has problems and needs

service. (Helpful isn’t it!)

If the Online light is on steady red, and the toner save light

is off, there could be a number of problems. Either there is a paper

jam, the front cover is open, or the toner cartridge is empty.

If the Online light is on blinking Green, and the toner save light

is off, there could also be a number of problems/reasons. If the

printer is receiving data, the Online/Error LED will blink slowly.

If the printer is printing, the Online/ Error LED will blink fast.

The Online/ Error LED will also blink if it is in the manual feed

mode, and no paper is in the manual feeder, or if the “Cancel”

button was pressed while the printer was receiving data.

|