Remanufacturing

the Lexmark T430 Toner Cartridge

0360

The T430 series of printers

use cartridges that look very similar to the T-420; basically they

are a modernized version of it. There are four different cartridges

for these machines. Two high yield, two low yield. Return Program

and Non-Return are available for both.

First released in January 2005, the T430 series are based on the

Lexmark 4048 32ppm, 1200dpi engine. So far only three models have

been released, the T430, T430d, and the T430dn. Both come standard

with duplex capabilities and a fast 366 MHz processor that gets

the first page out in less than 8 seconds. These machines are quite

an upgrade to the T420. The T420 ran at 22ppm, and used a 200MHz

processor.

As stated above, there are actually four cartridges currently available

for these machines. They are as follows:

| Part |

Type |

List$ |

Yield |

| 12A8425 |

High yield Return |

$273.00 |

12,000 |

| 12A8420 |

Standard Return |

$172.00 |

6,000 |

| 12A8325 |

High Yield NON-Return |

$304.00 |

12,000 |

| 12A8320 |

Standard NON-Prebate |

$162.00 |

6,000 |

As with all the newer Lexmark cartridges, the PCR is not in the

cartridge it’s in the printer. The wiper blade inside the

cartridges uses a PCR cleaner to keep the PCR clean. Because these

cartridges use ARD chips, only the Non-Return cartridges can be

remanufactured until new or repair chips are released. It should

also be noted that because of the play between the toner hopper

and the OPC drum, a shipping lock should be installed in every cartridge.

This holds true even if you are going to hand deliver the cartridge.

Taking test prints, as well as some common cartridge/machine problems

will be covered at the end of this article.

-

T430 black toner. Exact gram weights are under investigation

-

Long life OPC Drum (Optional, T420 may work testing is ongoing.

-

Wiper Blade

-

Shipping Lock

-

New White Developer Roller Shims (Optional)

-

Drum lubricant

-

Cotton Swab

-

Isopropyl Alcohol

-

Poly Wipes Cotton Pads

1) Vacuum the exterior of the toner cartridge.

2) Place the cartridge on the bench drum side down, and the toner

supply towards you.

3) With the spring hook, remove the two springs from each end of

the cartridge. The right side is easy to see, the left is somewhat

recessed. See Figures 1 & 2

4) Bend out the two side panels to release the hopper. See Figure

3.

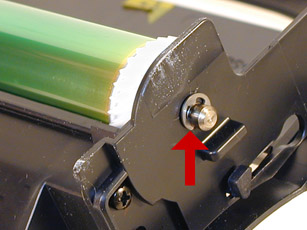

5) Remove the E-Ring from the small helical (white) gear end of

the drum

axle. There is no need to remove the other E-ring. See Figure 4

|

|

Figure 1 |

Figure 2 |

|

|

|

Figure 3 |

Figure 4 |

6) Slide the Drum Axle out of the cartridge. See Figure 5

7) Gently lift the Drum and Drum spring up and out of the cartridge,

and place in a light protected area. Be careful not to lose the

spring from the small white gear. Its purpose is to keep the drum

from rotating backwards. See Figure 6

Cleaning out the waste chamber can be done two ways. The easiest

way is to remove the drum cover, and then the two screws, and blade.

The second way is also easy, it just is somewhat more time consuming.

This method entails removing four screws, two from each side of

the cartridge, and then the blade and two screws. The first method

is covered in steps 8-9; the second is covered in steps 10-11

8) FIRST METHOD: To remove the drum cover, Bend the cover out in

the middle of the cover so that the two side pins are released.

See Figure 7.

9) Once the two small pins are released, slide the large tab on

the cover out through the large hole in the side wall of the cartridge.

See Figure 8

|

|

Figure

5 |

Figure

6 |

|

|

Figure

7 |

Figure 8 |

10) SECOND METHOD: Remove the two screws on each

side of the waste chamber. (Four screws total). See Figures 9 &

10.

11) Remove the waste chamber from the cartridge shell.

12) Remove the two screws and the wiper blade, from the waste chamber.

Vacuum it clean.

See Figure 11

13) Make sure the foam seal on the bottom of the wiper blade is

not torn or the cartridge may leak. See Figure 12

|

|

Figure

9 |

Figure

10 |

|

|

|

Figure

11 |

Figure

12 |

14) Coat the Wiper Blade with your preferred

lubricant, replace the blade and two screws into the cartridge.

See Figure 13

15) Install the waste chamber into the cartridge shell, and install

the 4 screws. See Figure 14

16) If it was removed, install the drum cover. Install the large

tab through the hole, and bend the cover in the middle so that the

pins on both sides fit into their respective holes. See Figure 15

17) On the toner hopper, remove the Doctor Blade Spring by pressing

down on the center of the spring. See Figure 16

|

|

Figure

13 |

Figure

14 |

|

|

|

Figure

15 |

Figure

16 |

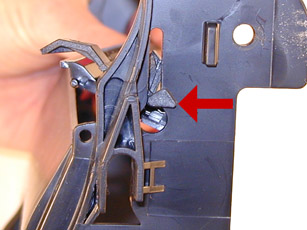

18) On the left side of the Developer Roller there is a small metal

copper colored bushing, take a small screwdriver, press the contact

plate down and pry the bushing off the shaft. See Figures 17 &

18

19) Remove the star drive gear from the opposite side of the developer

roller, remove the developer roller. The star gear has a very tight

fit. See Figure 19

NOTE: Always remove the Doctor Blade Spring before removing the

Developer Roller, failure to do this will allow the Doctor Blade

to slide down from its original position.

|

|

Figure

17 |

Figure

18 |

|

|

|

Figure

19 |

|

20) Remove the fill plug from the hopper. See Figure 20

21) Vacuum the Toner Hopper clean.

22) With a cotton swab dipped in alcohol, clean the Blue Developer

Roller seals located on either end of the developer roller section.

This also a good time to clean the bottom edge of the Dr. Blade.

See Figures 21 & 22

23) Carefully vacuum or blow off the Developer Roller, Be careful

not to touch the roller with your hands, or to damage this roller

in any way.

24) If the OEM developer roller spacers are damaged, they should

be replaced. The shims used on all previous Lexmark cartridges will

work here also. Damaged shims will allow toner to leak out of the

cartridge. See Figure 23

|

|

Figure

20 |

Figure

21 |

|

|

|

Figure

22 |

Figure

23 |

25) Place the keyed end of the Developer Roller into the cartridge,

and install the roller. Install the metal bushing. Turn the bushing

so that the oblong side locks into the spring contact. Install the

star gear, note that the gear and shaft are both keyed. Do not force

the gear on as it will be damaged. See Figures 24, 25 & 26.

26) Install the Doctor Blade Spring. See Figure 27

|

|

Figure

24 |

Figure

25 |

|

|

|

Figure

26 |

Figure

27 |

27) Fill the hopper with the appropriate amount of toner. Install

the Fill Plug. See Figure 28

28) Lightly coat the drum with your preferred lubricant.

29) With the cartridge upside down and the waste chamber facing

you, place the OPC Drum into the cartridge with the white gear side

of the drum to the right side of the cartridge. Make sure that the

spring is facing down, and is in between the two slots. (The slots

are only on the right side). See Figure’s 29 & 30.

30) Install the Drum Axle pin into the large gear side of the drum.

This is the opposite side from where the axle was removed. The Axle

must be installed this way to prevent the axle from bending and

damaging

the drum ground contact located inside the drum. See Figure 31

|

|

Figure

28 |

Figure

29 |

|

|

|

Figure

30 |

|

31) Install the E-Ring on the end of the axle. See

Figure 32

32) Spin the drum for a few revolutions towards the waste chamber

to

ensure the drum and wiper blade are properly lubricated.

33) Make sure both springs are in their respective holes in the

cartridge side walls. See Figure 33

34) Take the Toner Hopper and install it straight in. Bend out

the side wall of the cartridge so that the top pins are able to

lock in place. Make sure that the two front pins are in their slots.

See Figures 34, 35, & 36

|

|

Figure

34 |

Figure

35 |

|

|

|

Figure

36 |

|

35) With spring hook, replace both springs on to the

Toner Supply Chamber. See Figures 37 & 38

36) If this is a Prebate cartridge, the chip must

be replaced. Remove the screw, and remove the old chip. Install

the new chip, and replace the screw. See Figure 39

37) A shipping lock must now be installed. This lock should be

used even if you are going to hand deliver the cartridge. It will

prevent the toner hopper from coming in contact with the OPC Drum,

and causing damage to either the Drum or the Developer Roller. Press

the two red tabs into the sides of the cartridge as indicated. See

Figure 40

|

|

Figure

37 |

Figure

38 |

|

|

|

Figure

39 |

|

Running Test Prints:

Menu Settings Page:

1)Make sure that the ready light is on.

2)Press and release the “MENU” button until “Utilities

Menu” appears on the display

3)Press “SELECT”

4)Press and release the “MENU” button until “Print

Menu” appears on the display

5)Press “SELECT”

6)The menu settings page will print. If the machine is the network

version, an addition network settings page will also print

Print Quality Test Pages:

1)Turn the printer off.

2)Press and hold the SELECT and RETURN buttons, turn the printer

on.

3)Release the buttons once “PERFORMING SELF TEST” displays.

4)Select “Prt Quality Pgs”.

5)Three pages will print. Two graphics pages and an information

page.

If you have ever tried to run these pages from a T420 machine,

this is much, much easier!

Printer Trouble shooting

All the error messages below 900 are in English, and no explanation

is needed. All messages above 900 call for service. We will update

this as soon as the service manual is available.

Common toner cartridge problems:

Scratched drum this is shown by a very thin, perfectly straight

line that runs from the top to the bottom of the test page.

Chipped drum This will show as a dot or series of dots that repeat

3 times per page.

Light damaged drum This will show up as a shaded area on the test

print that should be white. Again this will repeat 3 times per page.

Bad wiper blade This will show as either a gray line approximately

1/8" thick, or as shading across the entire page. In either

case there will be a film of toner on the drum surface.

Weak Dr. Blade Spring This will usually show as shaded areas on

one or both sides of the page.

Changing the Printer Density

1)Make sure that the ready light is on.

2)Press and release the “MENU” button until “Quality

Menu” appears on the display.

3)Press “SELECT”.

4)Press and release the “MENU” button until “Toner

Darkness” appears on the display.

5)Press “SELECT”.

6)The settings can be changed from 1 to 10 with 8 being the default

|