Re-manufacturing the Lexmark E120 Toner and Drum Cartridges

0373

The Lexmark E120 was introduced in February 2006. The E120 engine is a new low cost engine that in some ways is a bit strange, but it works well, and will most likely sell well too.

The new machines are based on a Lexmark 19ppm, 600 DPI engine. With a street price of around $149.00(March 2006), these machines should be very popular. As with all Lexmark cartridges these days, they do have a chip that shuts the cartridge down after use on the return versions. The code in this chip is new, and at the time of this writing new replacement chips are actively being worked on. Check with you supplier for availability. There are also different cartridges used for different regions of the world. It is too soon to say for certain, but as with other new Lexmark series, I think it is a safe guess that it is the chips that are different.

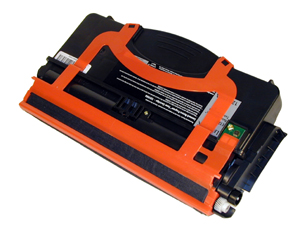

There are two cartridges used for this engine, a toner and drum unit. The toner cartridge is rated for 2,000 pages and the drum unit is rated for 25,000. No high yield cartridges are available at this time. These machines also have standard and Return program (Prebate) cartridges and all have chips. The “Return” chips must be replaced each cycle. The drum units are the same word-wide. We have included the instructions for the drum cartridge as well as they are so simple to do. Testing is on-going so at the time of this writing, we do not know if a drum or wiper blade will last another cycle. Preliminary test indicate they will, but not enough tests have been run to say for certain. There are no chips on the drum units.

The drum units are installed and removed from the back of the printer, and the toner from the front. A little strange but as these machines have such a small footprint, understandable. I just wonder what the customer reaction to that will be.

New machines ship with a 500 page starter cartridge, so new owners will be looking for cartridges fairly quickly.

A listing of the cartridges available as well as pricing follows:

*Pricing in USA as of March 2006

The only machines we have found so far based on this engine are the Lexmark E120, and E120n

How to take test prints as well as troubleshooting are covered at the end of the article.

-

Lexmark E120 toner 80g (Preliminary weight testing is on-going)

-

Toner Magnet cloths

-

Lint-free synthetic cotton 4"x 4" pads

-

99% pure Isopropyl Alcohol

-

Cotton Swabs

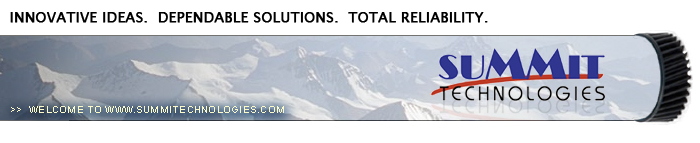

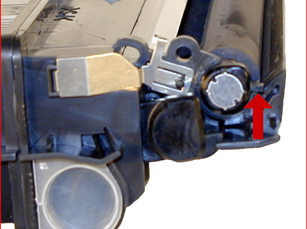

1) Remove the fill plug from the right side of the cartridge. (Developer roller facing away from you). Dump out any remaining toner from the hopper. See Figure 1

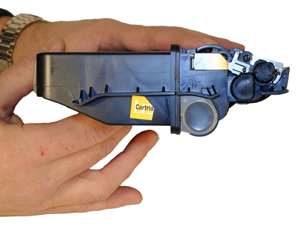

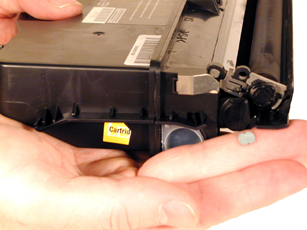

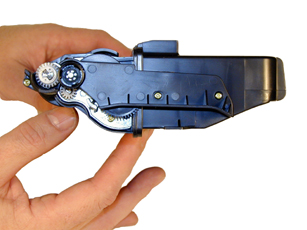

2) On the left side, remove the 2 small screws and the gear cover. See Figure 2

|

|

|

Figure 1 |

Figure 2 |

3) Remove the center screw on the developer roller cover. See Figure 3

4) Lift up the developer roller cover from the center, and remove. Be careful not to damage the plastic pins on the cover. See Figures 4 & 5

|

|

|

Figure 3 |

Figure 4 |

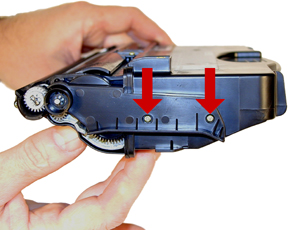

5) Remove the doctor blade spring. The doctor blade is now loose. Carefully lift it out, watching the contact spring on the right side. Also, be careful not to damage the retaining blade that is located under the doctor blade. See Figures 6, 7, & 8

|

|

|

Figure 5 |

Figure 6 |

|

|

|

Figure 7 |

Figure 8 |

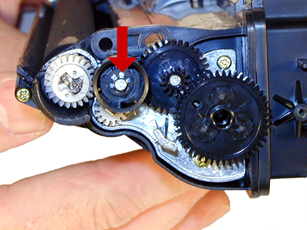

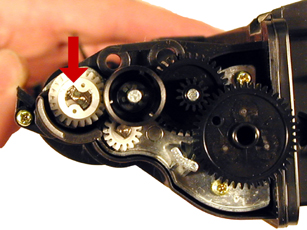

6) On the large black drive gear, there is a locking star washer pressed onto the shaft. With a small pair of wire cutters, cut the old washer off, and remove. You can try to bend up the different legs of the washer, but that is very time consuming, and most likely at least one leg will break anyway and the washer will still have to be replaced. See Figures 9 & 10

|

|

|

Figure 9 |

Figure 10 |

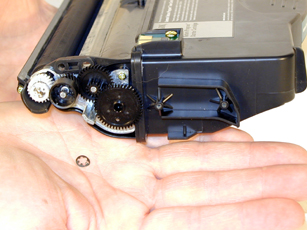

7) Remove the large black drive gear. Make sure you don’t loose the small flat washer from under where the star washer was. See Figure 11

8) On the white developer roller gear, take the tips of your small wire cutters, and place them into the two small holes. Spin the gear so the metal shaft is in the slot on the opposite side of the gear. Remove the gear. See Figures 12 & 13.

|

|

|

Figure 11 |

Figure 12 |

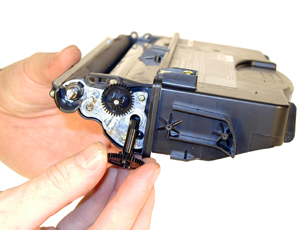

9) Remove all the gears. See Figures 14, & 15

|

|

Figure 13 |

Figure 14 |

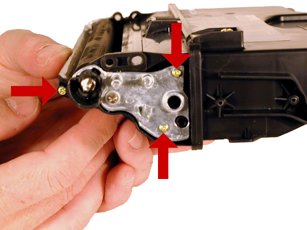

10) Remove the three screws and gear alignment plate. See Figures 16 & 17.

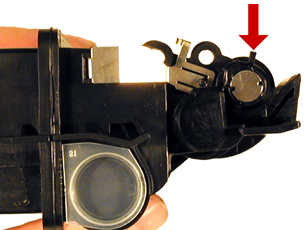

11) With a small flat head jeweler’s screwdriver, pry off the metal lock from the developer roller bushing. See Figure 18

|

|

|

Figure 15 |

Figure 16 |

|

|

|

Figure 17 |

Figure 18 |

12) Turn the developer roller bushing so the plastic tab is facing up. See Figure 19

13) Lift the developer roller out of the cartridge. The bushing will come off with the roller. See Figure 20

|

|

|

Figure 19 |

Figure 20 |

14) Clean out any remaining toner from the hopper. Make sure the developer roller retaining blade does not get damaged! See Figure 21

15) Wipe the developer roller down with a clean lint free cloth. Testing is ongoing, but for now, do not use any chemicals to clean it.

16) Re-install the developer roller. Spin the plastic bushing so it is locked in place. Install the metal locking bar, note that the left side fits into the small notch, and the right side is flush with the hub. If the small metal plate fell off the bushing, replace it. See Figures 22, 23, & 24

|

|

|

Figure 21 |

Figure 22 |

|

|

|

Figure 23 |

Figure 24 |

17) Install the gear axle plate, and three screws. See Figure 25

18) Install the gears. The large gear with the long shaft fits onto the toner agitator bar inside the hopper. Spin it a few times and listen to make sure it is engaged properly. On the large drive gear, make sure the flat washer is in place, and install a new star lock washer. Make sure the lock washer is pressed down fully against the base of the gear. Lastly on the developer roller drive gear, spin the gear by the two small holes while holding the developer roller in place. This will lock the gear on to the shaft. See Figures 26, 27 & 28

|

|

|

Figure 25 |

Figure 26 |

|

|

|

Figure 27 |

Figure 28 |

19) Clean the doctor blade and install. Make sure the metal tab on the right side fits into its slot. See Figure 29

20) Install the doctor blade spring. See Figure 30

|

|

|

Figure 29 |

Figure 30 |

21) Install the developer roller cover and screw. See Figure 31

22) Install the gear cover and two screws. See Figure 32

|

|

|

Figure 31 |

Figure 32 |

23) Fill hopper with E120 toner, replace the fill plug. See Figure 33

24) Replace the chip. See Figure 34

|

|

|

Figure 33 |

Figure 34 |

25) If the cartridge cover is available, wrap the cartridge as indicated. This cover helps protect the developer roller from damage. Aftermarket covers are in development. See Figure 35

Drum Cartridge

26) On the gear side of the drum unit, remove the E-ring from the drum axle shaft. See Figure 36

|

|

|

Figure 35 |

Figure 36 |

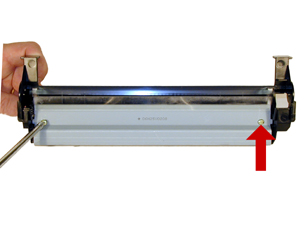

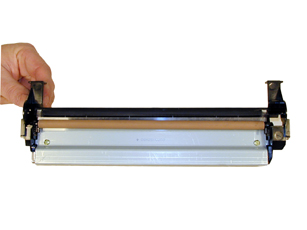

27) Slide the drum axle out from the drum. See Figure 37

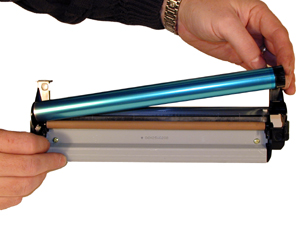

28) Remove the drum. See Figure 38

|

|

|

Figure 37 |

Figure 38 |

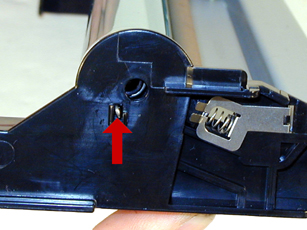

29) From the right (gear) side, remove the PCR assembly. (The spring loaded holder may come with it.) See Figure 39

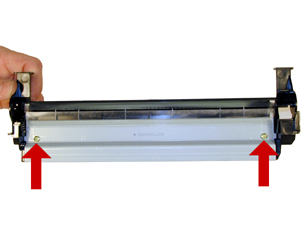

30) Remove the 2 screws from the wiper blade, remove the blade. See Figure 40

31) Clean out the waste toner.

|

|

|

Figure 39 |

Figure 40 |

32) Clean and coat the edge of the wiper blade with your preferred lubricant. Install the blade and 2 screws. See Figure 41

33) Clean the PCR and install. Make sure the black spacers are orientated towards the back of the wiper blade as shown. See Figure 42

|

|

|

Figure 41 |

Figure 42 |

34) Coat the drum with your preferred lubricant, install the drum. Make sure the small spring on the non-gear side fits into the slot in the plastic cartridge wall. See Figures 43 & 44

|

|

|

Figure 43 |

Figure 44 |

35) Install the drum axle shaft from the gear side of the drum. Install the E-ring. See Figure 45

|

|

Figure 45 |

Printing test pages

1) With the printer at the ready state, press the Continue button. The printer will print the menu settings page and network setup page if so configured.

Repetitive defect chart

|

|

| Lower Fuser Roller |

17.8mm (Printer) |

| Toner Feed Roller |

18.7mm (Toner Cart.) |

| PCR |

29.0mm (Drum Cart.) |

| Paper Pinch Roller |

30.4mm (Printer) |

| Developer Roller |

36.1mm (Toner Cart.) |

| Fuser Exit Roller |

37.9mm (Printer) |

| Transfer Roller |

48.1mm (Printer) |

| Paper Feed Roller |

56.2mm (Printer) |

| Upper fuser Roller |

62.2mm (Printer) |

| Drum |

74.1mm (Drum Cart.) |

| Paper pickup Roller |

92.4mm (Printer) |

Printer error codes. (Light sequences)

The E120 does not have an LCD display. It has a panel of lights to indicate problems. Some of the more common are listed below. In some cases, the same sequence of one light on, and another blinking will have different meanings. The difference is the amount of times the blinking light blinks. The first four sequences listed will give you a good idea of what I mean.

Error Light ON, Ready light BLINKING (4x); Cartridge region mismatch. Wrong chip is installed on the cartridge.

Error Light ON, Ready light BLINKING (3x); Missing/defective cartridge.

Error Light ON, Ready light BLINKING (1x); Door open

Error Light ON, Ready light BLINKING (8x); Toner low

Error Light BLINKING, Ready light BLINKING (1x); Replace the Drum unit.

Some light sequences have a primary and secondary sequence. The secondary sequence can be seen by pressing the CONTINUE button twice quickly.

Here is an example of the Primary and secondary sequence:

Primary: Toner Low light ON, Error light Blinking, Secondary: Toner low ON, paper jam Blinking, Error ON; Missing/defective cartridge

Most of the others deal with various paper jams. All are listed in the user manual.

|